In today’s competitive industrial landscape, managing heavy loads efficiently and safely isn’t just an operational concern — it’s a strategic advantage. Among the array of material-handling equipment available, jib cranes have emerged as indispensable tools in enhancing workflow, reducing physical strain on workers, and optimising facility space. Particularly when supplied by a knowledgeable distributor with deep industry expertise, jib cranes help companies transform how they move and lift components on the shop floor.

In the UK, Turbo Vacuumentation Ltd has established itself as a trusted source of high-quality jib crane solutions, offering equipment from leading manufacturer Schmalz as well as bespoke designs tailored to unique manufacturing challenges.

What Is a Jib Crane and How Does It Work?

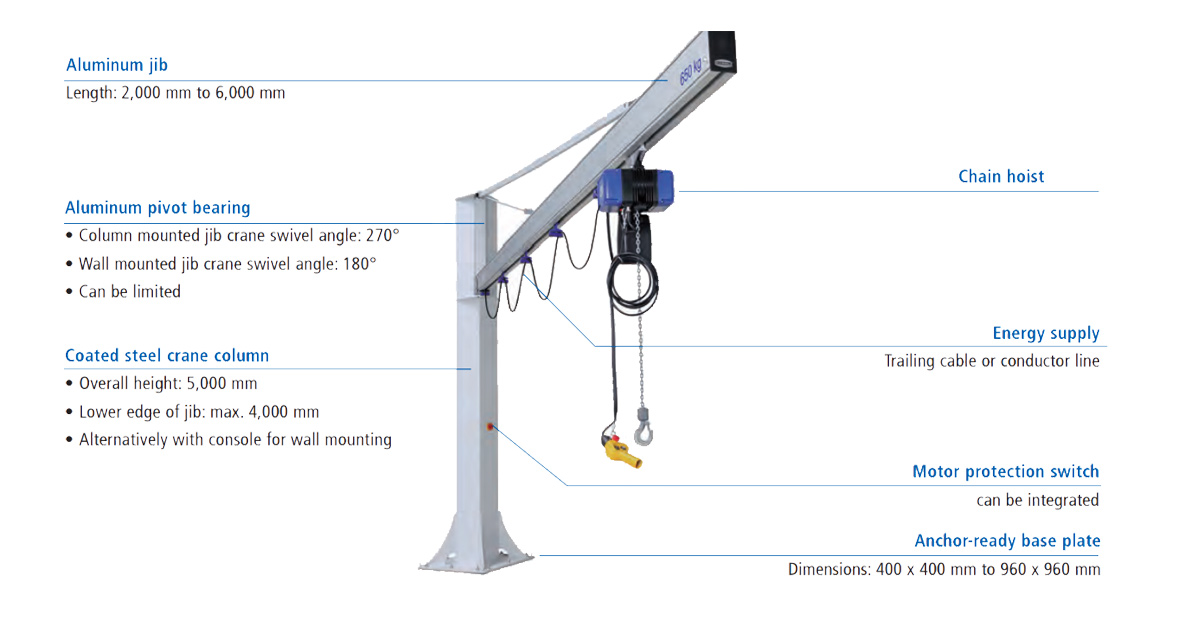

At its core, a jib crane is a type of overhead lifting device designed around a horizontal boom (the “jib”) that rotates around a vertical support column or wall mount. The crane arm swings smoothly in an arc, enabling the lifting and lateral movement of loads within a designated workspace — typically without requiring extensive floor space or large overhead gantry systems. This design makes jib cranes both cost-effective and highly versatile.

Two primary configurations dominate industrial applications:

- Column-mounted jib cranes — Installed on a freestanding support column, providing a swivel radius up to 270°. Ideal for larger work areas without existing structural support

- Wall-mounted jib cranes — Fixed directly to a wall or structural frame, conserving floor space and making them perfect for tight workshops or production lines.

Regardless of type, the central feature is the ability to lift, pivot and place heavy objects with minimal effort, often in confined or repetitive workstations.

Industrial Applications: Where Jib Cranes Excel

Jib cranes are used across a broad range of manufacturing sectors. Their flexible movement and adaptability make them suitable for virtually any environment where controlled lifting, placement or handling of heavy parts is needed.

- Assembly Lines and Production Cells

In manufacturing cells where components need to be moved between stations, jib cranes streamline the handling process. Workers can lift engines, sheet metal, moulded parts or other heavy elements and position them precisely without stopping the production line.

- Machine Tending and Tool Changeovers

Jib cranes are often deployed alongside CNC machines, presses, injection moulders and similar equipment to handle raw materials and finished goods. They can be paired with chain hoists or vacuum lifting devices for fast and ergonomic tool changeovers or part insertion.

- Loading and Unloading Materials

In warehouses or inbound docks, jib cranes make quick work of loading pallets or awkward loads from trucks or conveyors. Their ability to rotate and reach into tight spaces enhances turnaround times and reduces congestion on busy floors.

- Maintenance and Repair Tasks

Beyond production, jib cranes support maintenance crews by lifting motors, gearboxes, and other heavy service parts safely and efficiently.

- Integration with Vacuum Handling Systems

When combined with vacuum lifters or tube lifting systems — equipment that Turbo Vacuumentation Ltd specialises in — jib cranes become part of complete handling solutions that provide both lateral and vertical load movement. This integration is ideal where delicate handling or precise load placement is critical.

Key Benefits of Jib Cranes in Manufacturing Operations

Enhanced Workplace Ergonomics and Safety

One of the most compelling advantages of a quality jib crane system is the reduction of physical strain on workers. Instead of manually lifting heavy or awkward loads, operators can use a jib crane to move parts with minimal force, lowering the risk of musculoskeletal injuries and fatigue. Improved ergonomics directly correlates with reduced workplace accidents and lower workers’ compensation costs over time.

Space Efficiency and Smart Facility Layouts

Jib cranes make excellent use of vertical space, freeing up valuable floor area for other processes. Their semi-circular radius of movement means operators can access workstations or assembly points without needing multiple pieces of equipment or cluttering aisles. This compact footprint is especially valuable in facilities with limited square footage.

High Precision and Operational Speed

Thanks to their design, especially those built from lightweight materials like aluminium, jib cranes provide responsive movement and positioning accuracy. This means faster cycle times and more precise placement of parts — critical benefits in high-volume manufacturing and quality-driven processes.

Versatility and Accessory Integration

Modern jib cranes aren’t just standalone lifting arms. They can be configured with a wide range of accessories, including chain hoists, rope balancers, electric drives and vacuum lifters — all of which extend their utility across applications with varying load types and weights.

Durability and Low Maintenance

When properly engineered and installed, jib cranes offer long service lives with minimal maintenance. Components like low-friction transport trolleys and wear-resistant crane rails ensure that day-to-day operations remain smooth and predictable.

Whether integrating with vacuum handling systems, adding to existing overhead material-handling infrastructure, or designing new workstation layouts from scratch, a knowledgeable distributor accelerates deployment and protects investment value.

In industrial settings where efficiency, safety and precision matter, jib cranes deliver unquestionable value. Their blend of ergonomic design, flexible motion range, and integration potential makes them essential tools for modern manufacturing — from assembly and machine tending to material staging and logistics.

Choosing a reliable partner such as Turbo Vacuumentation Ltd — one that combines quality Schmalz equipment with engineering support — ensures that your jib crane investment maximises productivity, enhances workplace safety, and provides measurable performance improvements across your operations.

As factories continue to evolve towards smarter, safer, and more efficient workflows, jib cranes remain a foundational piece of the industrial mobility puzzle.