VacuMaster 180⁰ Rotate

Application

For handling large, flat and typically non-porous workpieces, for example:- Loading and unloading CNC laser cutting machines with metal plates

- Loading and unloading CNC machining centres with wooden boards or plastic sheets

- Handling and positioning glass panels and windows during production, framing and installation

Your Benefits

For handling large, flat and typically non-porous workpieces, for example:- Efficient, non-damaging handling of heavy loads

- To work ergonomically and protect operator health

- Excellent work safety and process reliability thanks to vacuum reservoir and audible warning device

- Long service life due to a robust mixture of steel, aluminium and high-strength plastic

- Low operating costs thanks to controlled vacuum generator with energy saving (Comfort version)

Design and Function

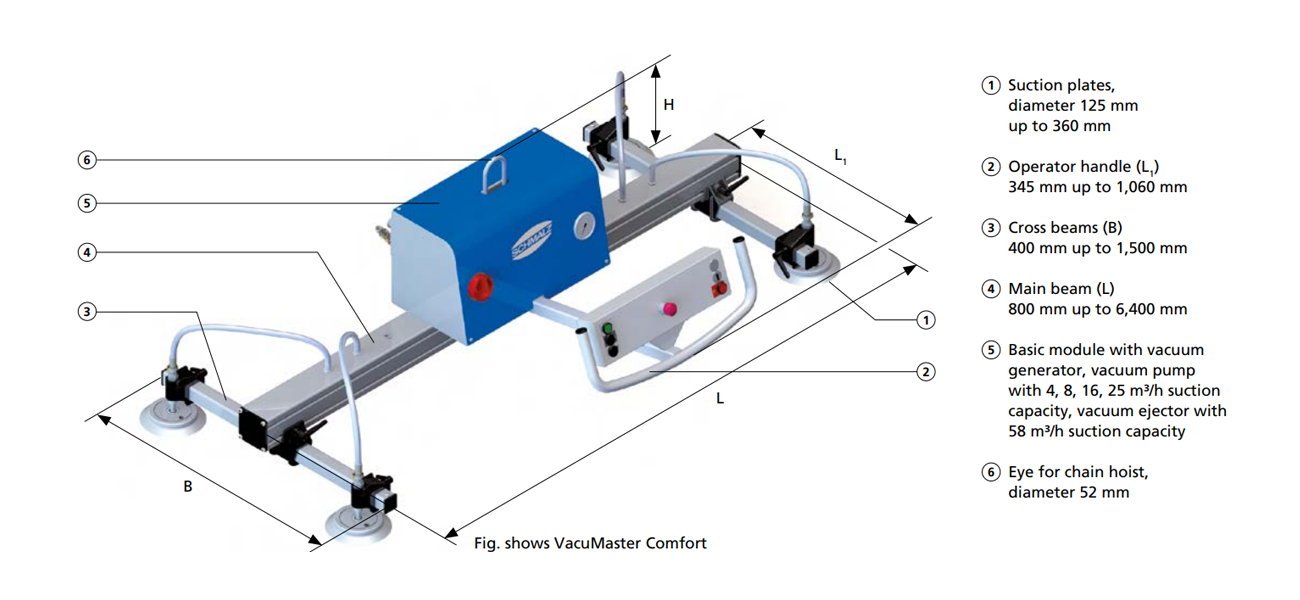

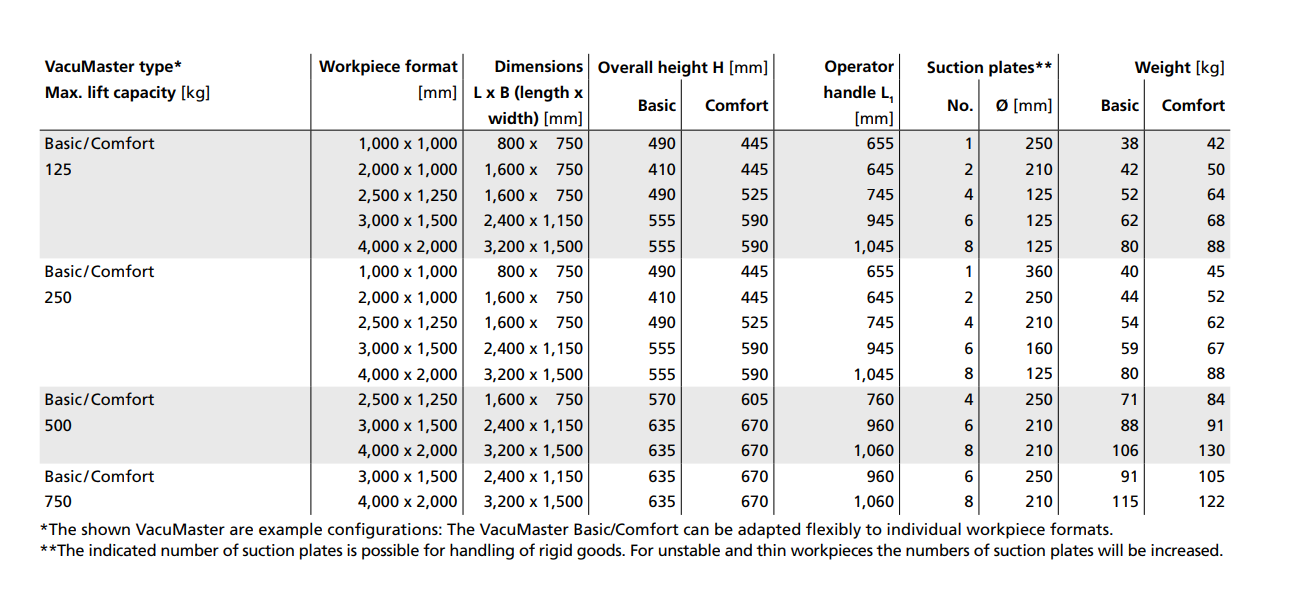

The vacuum lifting device VacuMaster has a modular design. Various basic modules, operator handles, load beams and suction plates allow you to customize the configuration. The necessary suction force is generated by the vacuum generator and transferred to the workpiece via the suction plates. For safety purposes, the aluminium load beam also serves as a vacuum reservoir. A chain hoist is required for lifting or lowering motion, which Schmalz offers along with a compatible crane system.

Our VacuMaster Range come with two control modules

The VacuMaster Basic’s versatile standard equipment makes it indispensable for many applications. In addition, the VacuMaster Comfort offers an operator handle that brings together all of the device’s controls as well as a controlled vacuum generator for reducing energy.