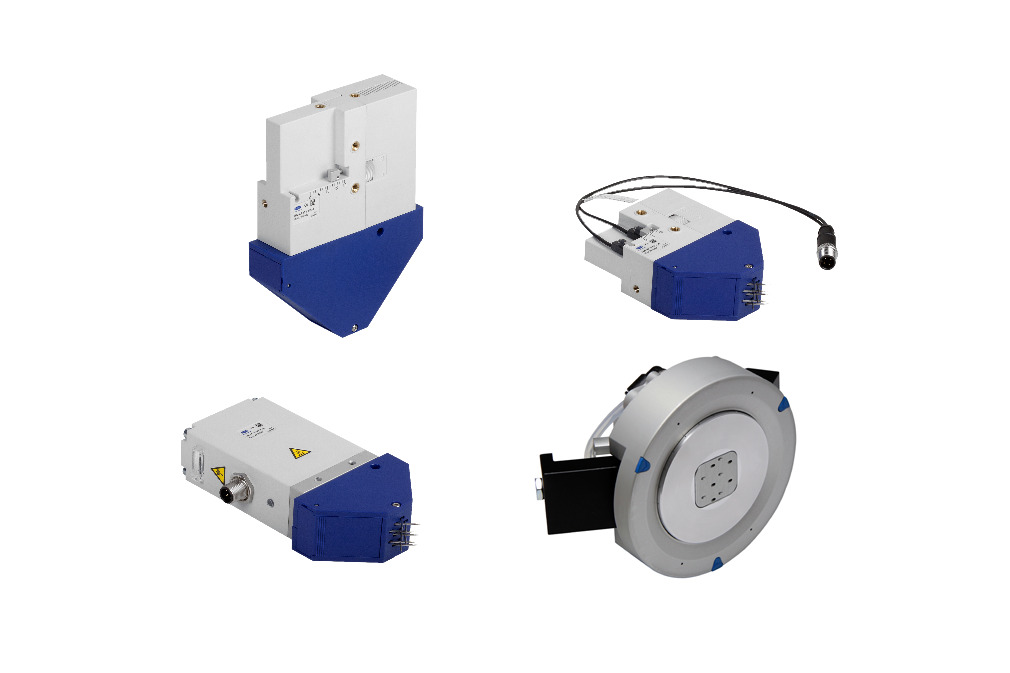

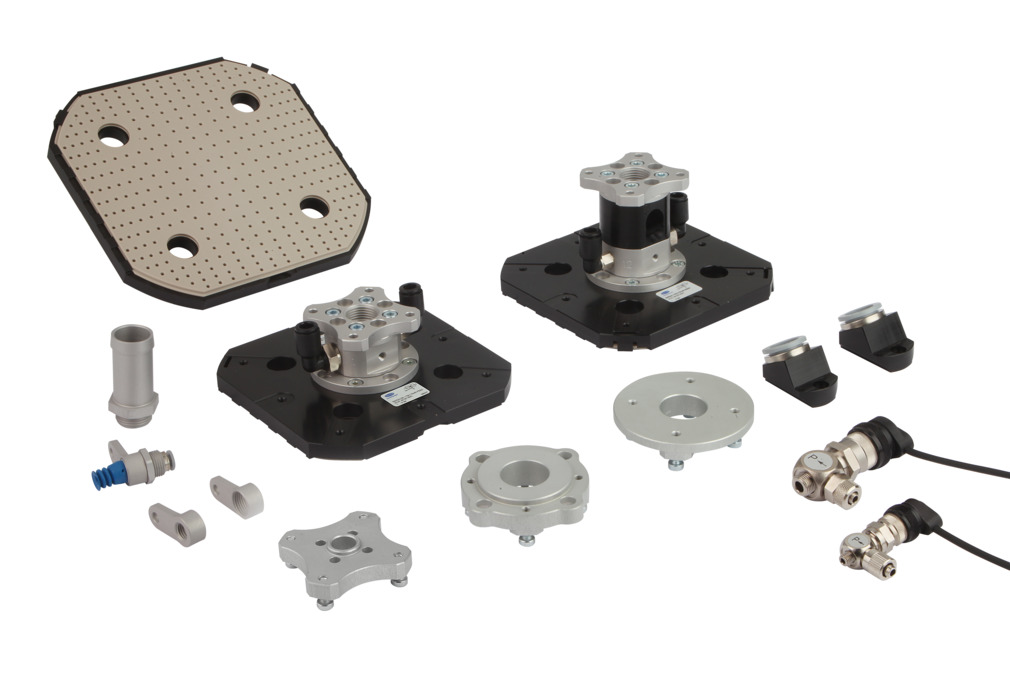

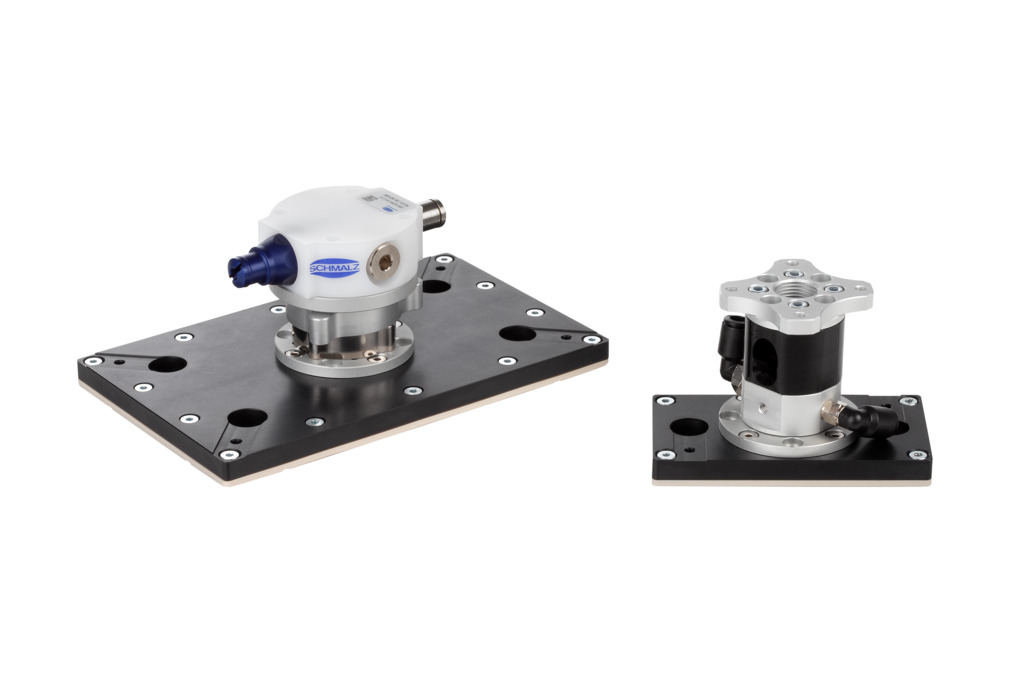

Special grippers can be used for applications in which regular suction pads cannot generate a vacuum. We offers a variety of special grippers with various shapes, sizes and principles of operation.

Special grippers can be used for applications in which regular suction pads cannot generate a vacuum. We offers a variety of special grippers with various shapes, sizes and principles of operation.