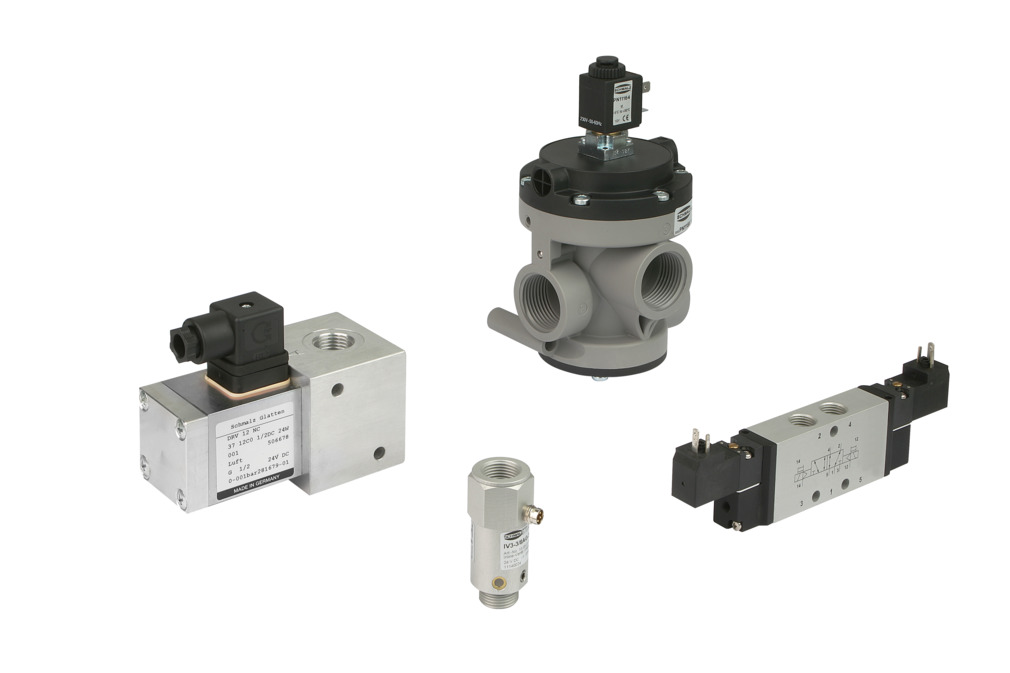

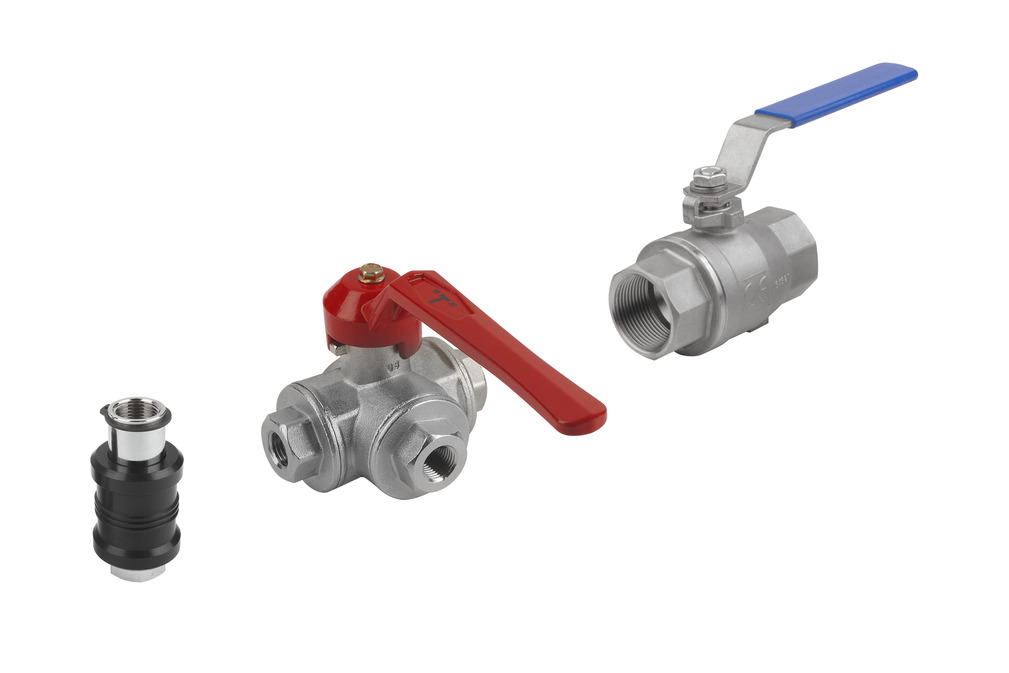

Valves are used to control the vacuum as well as the compressed air. The right valves can increase both the process reliability and the cost-effectiveness of the vacuum system.

Valves are used to control the vacuum as well as the compressed air. The right valves can increase both the process reliability and the cost-effectiveness of the vacuum system.