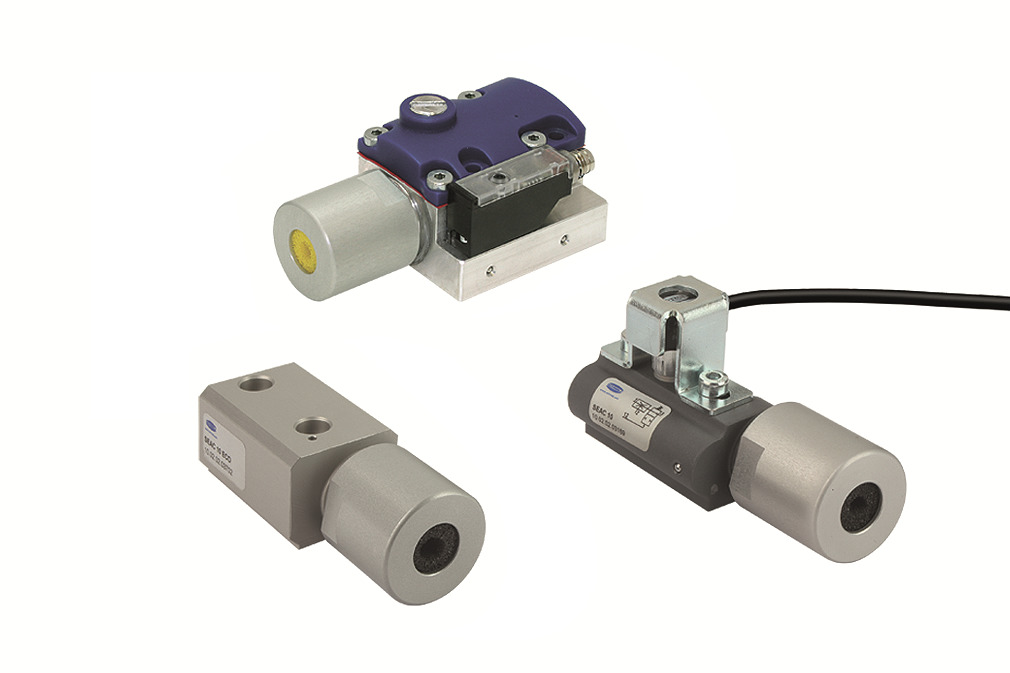

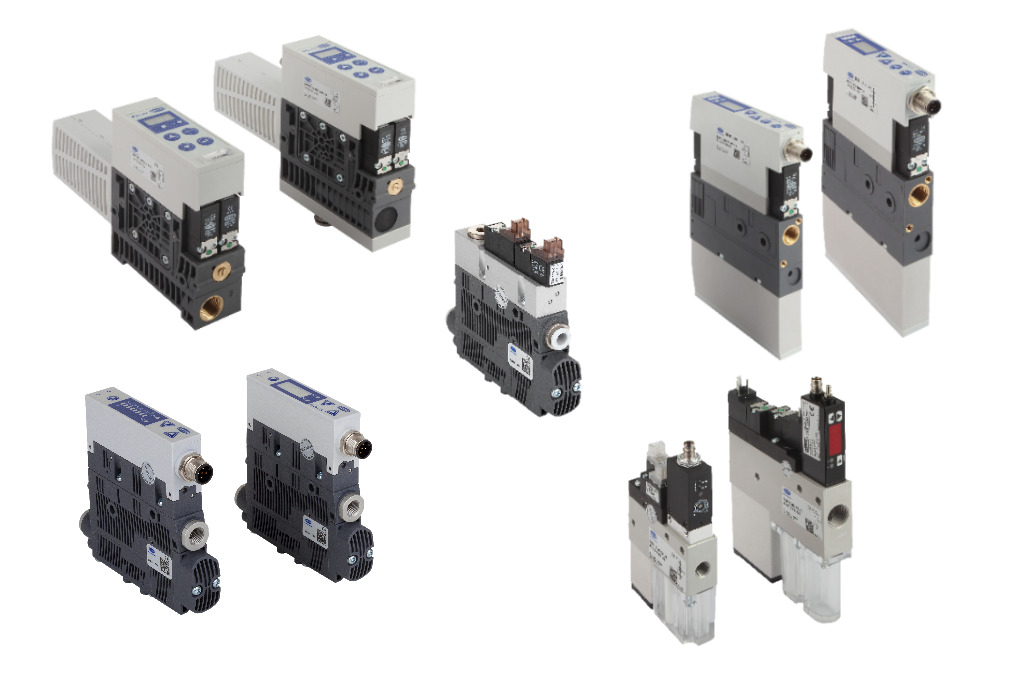

Vacuum generators provide the required vacuum. The vacuum is generated either pneumatically (ejectors) or electrically (pumps, blowers). Pneumatic vacuum generators implement short cycle times and can be integrated directly into the system due to their compact and lightweight design. Ejectors offer intelligent functions for energy and process control. Electrical vacuum generators are used in applications when compressed air is not available or if very high suction capacities are required.