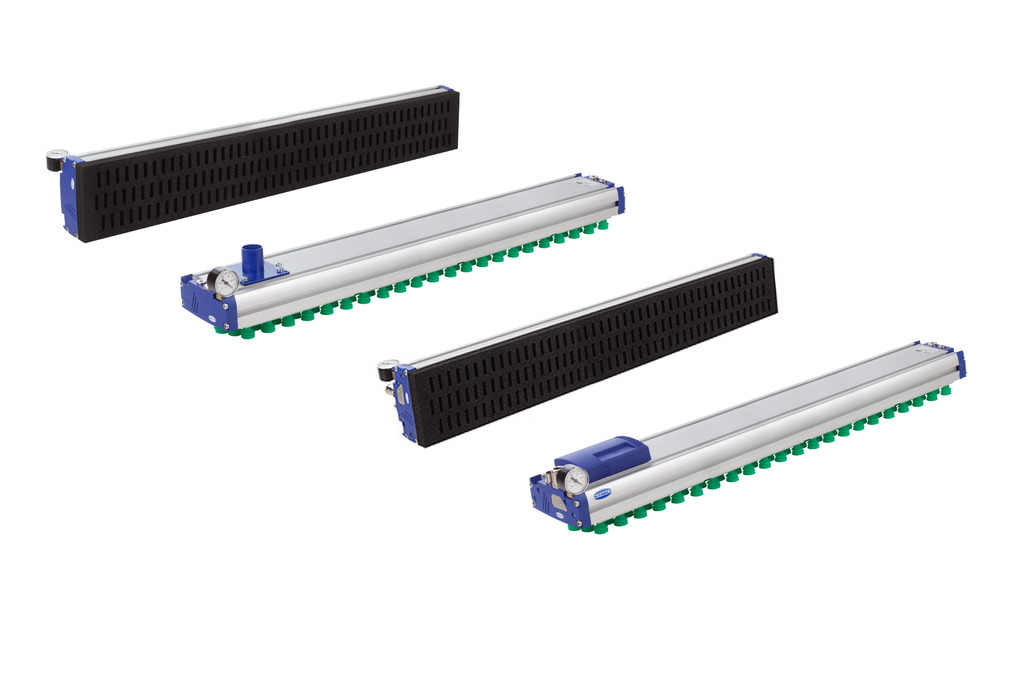

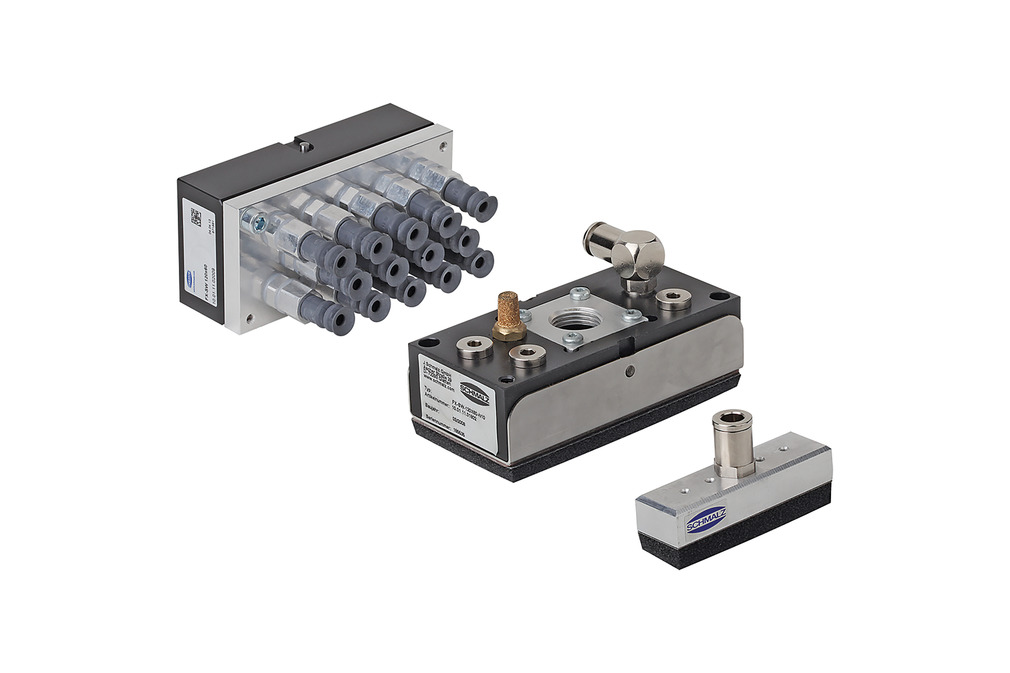

Area gripping systems and end effectors are gripping systems that can be attached directly on the robot. Area grippers are universal and are used in a huge range of robot applications. Vacuum end effectors are easy to configure from the modular system. They are particularly suitable for processes in the packaging industry.