Introduction to Jumbo Flex Tube Lifters

In today’s fast-paced industrial world, efficiency is key. Businesses are constantly seeking innovative solutions to enhance their operations and boost productivity. Enter Jumbo Flex Tube Lifters – a game changer in material handling! These versatile devices not only streamline the lifting process but also reduce workplace injuries associated with heavy lifting. Imagine a system that allows you to move large items effortlessly while improving your workflow. That’s precisely what Jumbo Flex Tube Lifters offer, making them an essential tool for many industries looking to optimise performance and safety on the job site. Let’s dive deeper into how these lifters work and explore the myriad of benefits they bring to your operations.

How Do Jumbo Flex Tube Lifters Work?

Jumbo Flex Tube Lifters operate on a simple yet effective principle. They utilise vacuum technology to lift and transport various materials with ease. This innovative design allows for smooth handling of items, reducing strain on workers.

The system consists of flexible tubes that connect to a powerful vacuum pump. When activated, the pump creates suction within the tube, gripping the object securely. Operators can then maneuver these lifters effortlessly across different surfaces.

Adjustable settings cater to various weights and shapes, making them versatile in any work environment. Whether lifting boxes or delicate components, Jumbo Flex Tube Lifters adapt seamlessly.

Additionally, they promote ergonomic practices by minimising physical exertion during lifting tasks. This not only enhances worker comfort but also boosts overall efficiency in operations.

Advantages of Using Jumbo Flex Tube Lifters

Jumbo Flex Tube Lifters bring a host of benefits to various industries. Their primary advantage is the ability to significantly enhance productivity. By efficiently lifting and transporting heavy materials, they reduce manual strain on workers.

Another key benefit is their adaptability. These lifters can handle different shapes and sizes, making them ideal for diverse applications. This versatility allows businesses to streamline operations without the need for multiple lifting devices.

Additionally, using Jumbo Flex Tube Lifters improves workplace safety. They minimise the risk of injury from awkward lifting techniques or excessive physical exertion.

Moreover, these lifters are designed with user-friendly controls that make operation simple and intuitive. This ease enhances employee satisfaction while contributing to a more efficient workflow.

Investing in Jumbo Flex Tube Lifters ultimately leads to increased efficiency within any facility, enabling teams to focus on core tasks rather than labor-intensive movements.

Applications of Jumbo Flex Tube Lifters

Jumbo Flex Tube Lifters are incredibly versatile tools that find their place in various industries. From manufacturing to food processing, these lifters simplify the handling of heavy materials.

In warehouses, they assist in moving bulky items with ease. This not only boosts efficiency but also keeps workers safe from potential injuries related to lifting.

In the packaging sector, Jumbo Flex Tube Lifters streamline operations by enabling quick and efficient loading and unloading processes. They can handle diverse products like bags or boxes without hassle.

Additionally, they’re a great fit for the pharmaceutical industry where precision is key. Their ability to lift sensitive products gently ensures quality control while maintaining productivity levels.

The adaptability of Jumbo Flex Tube Lifters allows them to cater to specialised tasks across sectors. This makes them an essential asset for businesses aiming for increased efficiency and higher productivity.

Maintenance and Safety Tips for Jumbo Flex Tube Lifters

Proper maintenance ensures the longevity of your Jumbo Flex Tube Lifters. Regularly inspect all components for wear and tear. Pay close attention to seals and tubes; any signs of damage can compromise performance.

Keep the lifting mechanism clean and free from dust or debris. A simple wipe down after usage can prevent buildup that may hinder operation.

Ensure that operators are trained on safety protocols. Proper training reduces accidents and enhances efficiency.

Check fluid levels regularly if your lifter uses pneumatic features. Adequate lubrication is essential for smooth operation, avoiding unnecessary wear on moving parts.

Maintain clear workspaces around the equipment. Clutter can lead to trips or falls, jeopardising both workers’ safety and equipment integrity. Prioritise a safe environment to maximise productivity without compromising well-being.

Buy Jumbo Flex Tube Lifters at Turbo Vacuumentation Ltd

If you’re looking to enhance your operations, consider investing in Jumbo Flex Tube Lifters. These innovative lifting solutions are available at Turbo Vacuumentation Ltd, a trusted provider of industrial equipment designed for efficiency and productivity.

At Turbo Vacuumentation Ltd, you’ll find a wide selection of Jumbo Flex Tube Lifters tailored to meet various needs across industries. Their expert team is ready to assist you in choosing the right model that fits your specific requirements.

Don’t settle for less when it comes to optimising your workflow. Embrace the advantages offered by Jumbo Flex Tube Lifters and experience increased efficiency like never before. Visit their website or contact them today to explore how these tube lifters can transform your operational capabilities and boost higher productivity!

Application

- Items weighing up to 50 kg that require frequent cycles.

- Easily operate with one hand for swift motion procedures.

- Single-finger and double-finger control is available for both right-handed and left-handed individuals.

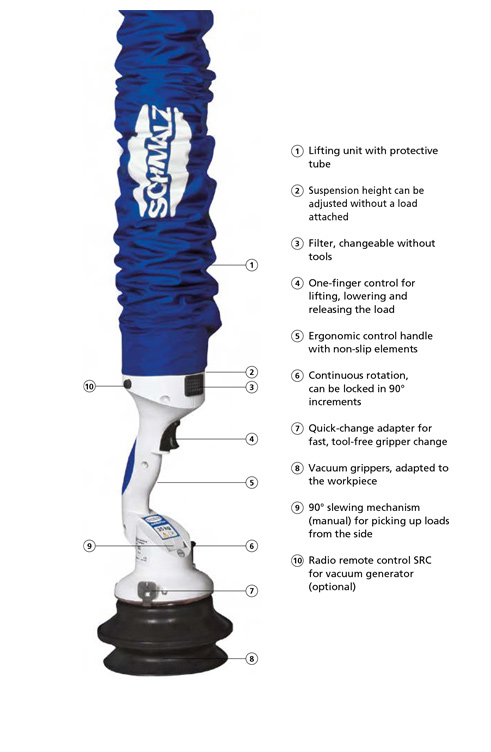

The Jumbo Flex vacuum tube lifter is a versatile tool for handling lighter goods up to 50 kg. Designed for ergonomic use and high cycle rates, this lifter provides comfort and efficiency for operators. Its control handle is designed to fit comfortably in the hand, allowing for extended periods of work without fatigue. The intuitive one-finger control makes lifting, lowering, and releasing loads effortless. With a wide range of features, the Jumbo Flex can take on any task that comes its way. It even has a quick-change system for easily replacing the vacuum grippers. Additionally, workpieces can be automatically rotated from a vertical position to a horizontal one with ease.

The Jumbo Flex Tube Lifters offer numerous other advantage:,

Decrease your energy consumption by up to 40% with just the push of a button:

The SRC radio remote control allows for easy shutdown and restarting of the vacuum generator on the operator handle. Simply press a button to activate the control, which operates without any need for an external energy source thanks to its built-in induction generator.

Decrease the noise level:

By attaching the SBB silencer box, the noise produced by the vacuum generator is minimised and its components are shielded from external debris. The mounting process onto the blower console is straightforward.

Ensuring cleanliness:

The STF dust filter is highly recommended to safeguard the vacuum generator from dirt particles. Additionally, it allows for quick and easy cleaning.

Thermal overload protection is a safeguard against excessively high temperatures:

By utilising the motor-protection switch MSS, the vacuum generator can easily be activated or deactivated while also being safeguarded against excessive currents. This convenient feature allows for seamless integration into the Schmalz crane column without requiring complex wiring, and it can also be locked as an added option.

Safekeeping of belongings:

The AB-JU storage rack is designed to safeguard the Jumbo Flex by providing a secure storage space for when it is not in use. This helps to protect both the lift tube and vacuum grippers.