In the ever-evolving landscape of automation and material handling, choosing the right gripping technology can make a world of difference in performance and efficiency. As industries strive to enhance productivity while maintaining safety standards, two popular contenders have emerged: vacuum grippers and traditional mechanical grippers. Each has its own strengths, weaknesses, and applications that cater to specific needs. Whether you’re in manufacturing or logistics, understanding these gripping systems is crucial for optimising your operations. Let’s have a look at the characteristics of vacuum gripping versus traditional mechanical grippers to discover which option may be more suitable for your business needs.

The Advantages and Disadvantages of Mechanical Grippers

Mechanical grippers have been a staple in automation for decades. They provide reliable performance and can handle a variety of objects with ease. Their design is often simple, allowing for quick maintenance and repairs.

However, mechanical grippers come with limitations. They rely on physical force, which means they can struggle with delicate or irregularly shaped items. This rigidity can lead to damage during gripping or release.

Another consideration is speed. While mechanical systems operate effectively at moderate speeds, they may not match the rapid cycle times needed in modern production lines.

Safety is also an important factor; mechanical grippers can pose risks if not properly designed or maintained. Injuries from pinch points are possible when using outdated systems without adequate safety features.

Despite these drawbacks, many manufacturers still favour them due to their cost-effectiveness and familiarity within existing processes.

What is Vacuum Gripping?

Vacuum gripping is an innovative solution that uses suction to handle a variety of objects. It operates on the principle of creating a vacuum between the gripper and the item being lifted. This suction holds items securely, making it ideal for different materials.

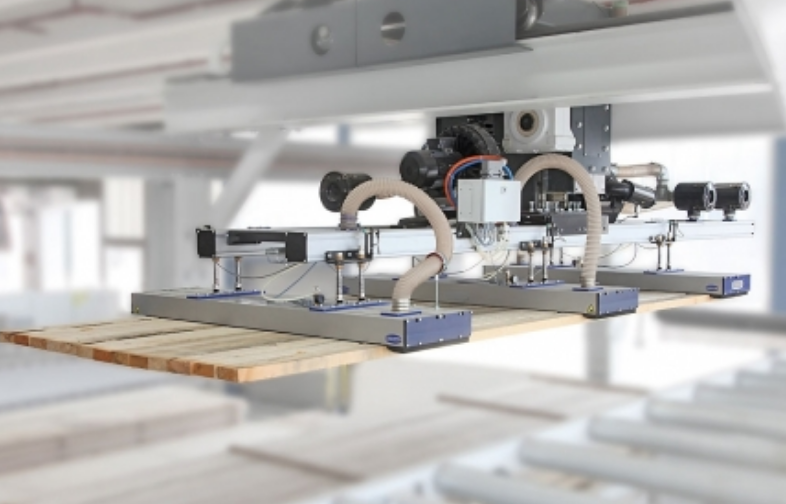

The technology can adapt to various shapes and sizes thanks to flexible designs like suction spiders or Layer Grippers. These systems are engineered for efficiency, ensuring quick handling without damaging delicate surfaces.

Industries ranging from packaging to automotive frequently utilise vacuum gripping due to its versatility. Whether moving glass sheets or fragile products, these systems enhance productivity by minimising risk and increasing safety in operations.

Implementing vacuum grippers often leads businesses away from outdated systems towards more advanced solutions that significantly improve performance while reducing labor costs. As automation continues to evolve, embracing such technologies becomes essential for maintaining competitive advantages.

Benefits of Vacuum Gripping over Traditional Mechanical Grippers

Vacuum gripping offers distinct advantages that set it apart from traditional mechanical grippers. One of the primary benefits is its exceptional adaptability. Vacuum systems can handle a variety of shapes and materials, making them ideal for diverse applications.

The lightweight design of vacuum grippers enhances efficiency in handling tasks. They reduce energy consumption and minimise wear on equipment. This translates into cost-effective operations over time.

Safety is another key factor. Vacuum grips provide a firm hold without exerting excessive force, reducing the risk of damage to delicate items during processing or transport.

Additionally, they operate with minimal maintenance compared to outdated mechanical systems. Reliable suction technology ensures consistent performance without frequent adjustments or repairs.

Their versatility allows businesses to implement innovative solutions tailored to unique needs across various industries – from packaging to automotive manufacturing – fostering improved productivity on all fronts.

Applications and Industries that Benefit from Vacuum Gripping

Vacuum gripping technology is transforming various industries with its unique applications. In the packaging sector, vacuum grippers excel at handling delicate items like glass containers and plastic bottles without damaging them.

The automotive industry also reaps benefits. These innovative solutions efficiently manage assembly line processes, ensuring that parts are securely held during manufacturing. This not only enhances productivity but also boosts safety.

In electronics, vacuum grippers handle sensitive components with precision. They minimise the risk of static damage while speeding up assembly tasks.

Food processing companies employ these systems for their efficiency and hygiene standards. Vacuum gripping ensures safe handling of food products while reducing contamination risks.

In addition, logistics and warehousing see increased operational efficiency through automated sorting systems using suction spiders to move goods quickly and safely across vast spaces. The versatility of vacuum grippers makes them indispensable across diverse sectors looking to modernise outdated systems.

Factors to Consider when Choosing between Vacuum and Mechanical Grippers

When deciding between vacuum gripping and mechanical grippers, several factors come into play. Start with the nature of your materials. Delicate or porous items may benefit more from vacuum systems, ensuring gentle handling without damage.

Consider the workplace environment too. If dust or debris is prevalent, mechanical grippers might offer more reliability. Their straightforward design can be less susceptible to contamination compared to suction cups.

Next, analyse your production speed requirements. Vacuum gripping often enhances efficiency in high-speed applications due to rapid actuation features.

Budget constraints are also vital. While innovative solutions like Special Gripping Systems can provide advanced functionality, they may require a higher initial investment than traditional options.

Think about maintenance needs. Mechanical grippers generally have fewer components that could fail over time when compared to complex pneumatic setups found in some vacuum systems.

Making the Right Choice for Your Business Needs

Choosing the right gripping technology for your business is a significant decision that can affect performance, safety, and productivity. Both vacuum gripping and traditional mechanical grippers offer unique benefits tailored to different applications.

Vacuum grippers provide versatility and innovative solutions for handling delicate or irregularly shaped objects. Their efficiency in picking up various materials without damaging them makes them increasingly popular across diverse industries. With advancements like Layer Grippers and suction spiders, organisations can enhance their automation processes while optimising costs.

On the other hand, mechanical grippers remain relevant due to their reliability in specific settings where high force application is necessary. However, outdated systems may not keep pace with modern demands for flexibility and cost-effectiveness.

When deciding between these technologies, consider factors such as material types, operational environment, desired throughput rates, and long-term investment goals. Aligning your choice with your specific needs will ensure you maximise both efficiency and productivity in your operations. Making an informed decision today sets the stage for success tomorrow!