In modern industrial manufacturing, the ability to move heavy loads safely, efficiently, and ergonomically can make or break operational performance. Among the backbone technologies enabling these capabilities are gantry cranes—versatile, robust lifting systems that have become indispensable across manufacturing floors, assembly plants, logistics hubs, and beyond.

But what exactly makes gantry cranes so valuable to industrial manufacturing businesses? And how do advanced systems like Schmalz crane solutions elevate those benefits even further? In this deep-dive article, we explore the real-world advantages and broad applications of gantry cranes, with a spotlight on the innovative engineering that Schmalz brings to the table.

What Are Gantry Cranes?

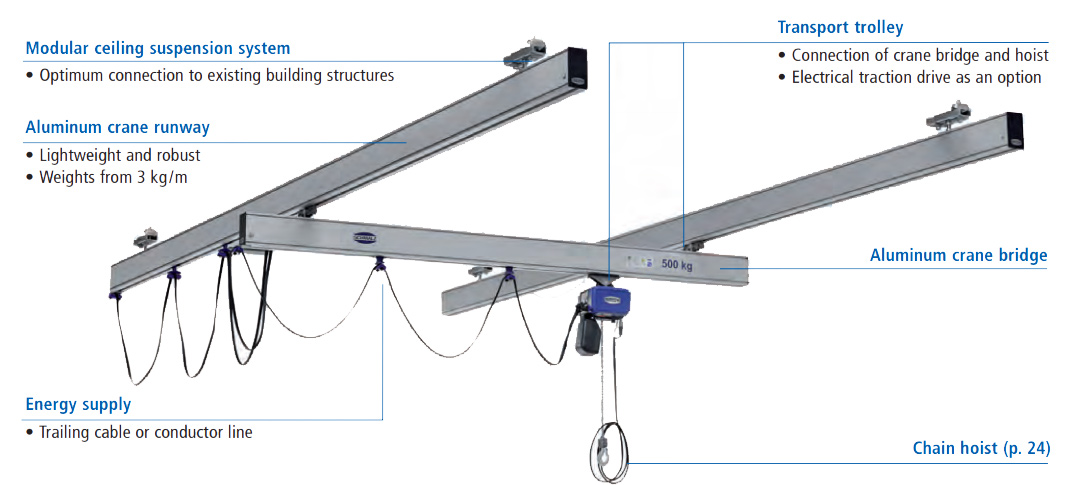

At their core, gantry cranes are lifting systems with a bridge (or beam) supported by legs that run on rails or tracks. Unlike fixed overhead cranes, gantry cranes can be mounted on floors, ceilings, or support structures depending on operational needs. They are engineered to traverse large workspaces horizontally while lifting loads vertically, providing three-dimensional handling capability.

In manufacturing, these cranes often form the backbone of internal material flow, enabling seamless movement of components and assemblies across production zones, staging areas, and packing stations.

Core Benefits of Gantry Cranes in Manufacturing

1. Transformational Efficiency and Productivity

Industrial manufacturing thrives on speed without compromise. Gantry cranes dramatically reduce material handling time by enabling swift, controlled movement of heavy parts between workstations.

Instead of relying on forklifts, manual labour, or conveyor bottlenecks, operators can reposition goods precisely where they’re needed—cutting delays and smoothing workflows.

For example, many Schmalz aluminum crane systems are designed for excellent low-friction running and lightweight operation, which reduces the effort required to move loads and enables faster positioning.

2. Enhanced Ergonomics and Worker Safety

Manual lifting of heavy loads is a leading cause of workplace injuries, fatigue, and lost time. Gantry cranes shift that burden from the operator to the system, enabling ergonomic transport with minimal physical strain.

Schmalz specifically engineers its crane systems to support ergonomically friendly operation, reducing the physical effort required by workers by over 60 % compared with conventional steel crane systems—helping companies promote healthier workplaces and reduce absenteeism.

This isn’t just about comfort; safer handling reduces risk and insurance costs while supporting compliance with occupational health standards.

3. Exceptional Flexibility and Modular Design

One of the greatest strengths of gantry cranes is adaptability. Modern systems—including those from Schmalz—feature modular architectures that can be tailored to diverse industrial environments. Whether you need a single-girder setup for lighter loads or a double-girder system for heavier assemblies, modular design means the crane can grow with your business demands.

Schmalz systems can be configured as single girder, double girder or monorail solutions—and paired with a range of lifting devices like chain hoists, rope hoists, vacuum lifters, or rope balancers.

This adaptability ensures crane systems can be tailored to specific ceiling structures, floor layouts, and workflow requirements.

4. Improved Precision and Load Control

Beyond lifting heavy loads, industrial manufacturing demands precision placement—whether it’s feeding a part into an automated assembly cell or positioning a component on a machining centre.

Gantry cranes excel at this with smooth travel and accurate stopping control. Lightweight aluminum crane profiles, balanced trolleys and optional motorised drives enable operators to position loads precisely, reducing errors and rework.

Schmalz systems are engineered with high-quality, wear-resistant profiles that support controlled, low-force movement—even under significant loads—making them ideal for high-precision environments.

5. Broad Operational Applications

Gantry cranes are not one-trick ponies. Their versatility means they serve across a wide range of manufacturing tasks:

- Assembly and sub-assembly lines: Easily move large components between stations.

- Machining and finishing cells: Position workpieces for CNC or other fabrication processes.

- Production staging and packing: Streamline loading/unloading operations in logistics.

- Tooling and die environments: Handle heavy dies, molds, and fixtures safely.

- Maintenance and changeovers: Lift and reposition equipment during plant changeovers or repairs.

At Schmalz, dedicated crane systems are widely used in “in-house production, mounting and logistics processes,” demonstrating their role as central material handling hubs across functions.

Why Schmalz Crane Systems Stand Out

While basic gantry crane technology is proven and powerful, Schmalz brings several distinct advantages that make their systems compelling for modern manufacturing operations:

• Lightweight Yet Strong Construction

Using high-quality aluminum profiles, Schmalz crane systems achieve an ideal weight-to-load ratio. Profiles are available in multiple thicknesses to support loads up to 1,200 kg, and extendable rail lengths up to 8 m help cover large spans within facilities.The result is effortless movement with minimal force—reducing operator fatigue and increasing cycle speeds.

• High Safety and Compliance

Safety is non-negotiable in industrial settings. Schmalz cranes are designed according to DIN EN 13001 standards and undergo independent finite element method (FEM) calculations for strength and load safety.

This rigorous engineering ensures not only reliability under load but confidence in long-term operation.

• Accessory and Integration Ecosystem

Schmalz offers an extensive range of accessories such as adjustable electric travel drives, cordless energy supply systems, and cushioned end stops, allowing each crane installation to be optimised for its specific workflow.

Moreover, seamless integration with vacuum lifters and other lifting devices creates a cohesive system that supports both heavy and delicate handling applications.

• Future-Ready Modularity and Scalability

Manufacturing requirements evolve, whether driven by product changes, automation initiatives, or facility expansions. Modular gantry crane systems allow businesses to adapt or expand their material handling footprints without wholesale reinvestment, preserving capital and extending the useful life of installed equipment.

Gantry cranes represent a foundational technology in industrial material handling, enabling safer, faster, and more precise workflows. When enhanced with advanced design and modular engineering, as in Schmalz crane systems, these solutions become strategic tools—not just equipment purchases.

Trusted UK Expertise with Turbo Vacuumentation Ltd

For UK manufacturers looking to implement or upgrade gantry crane systems, Turbo Vacuumentation Ltd stands out as a trusted and experienced distributor of Schmalz crane systems. With deep technical knowledge and a strong track record in material handling solutions, Turbo Vacuumentation works closely with businesses to design, supply, and support gantry crane systems tailored to exact operational requirements. Whether the need is for lightweight aluminum gantry cranes, fully integrated lifting solutions, or bespoke configurations for complex production environments, Turbo Vacuumentation can fulfil any gantry crane requirement from concept through to installation. To learn more about their Schmalz gantry crane offerings and expert support, visit:

https://www.turbo-vac.co.uk/crane-systems/gantry-cranes/

From ergonomic performance and reduced handling times to flexible integration and industry-leading safety standards, the benefits are clear: gantry cranes are not simply pieces of lifting equipment—they are catalysts for operational excellence in industrial manufacturing.