When it comes to lifting and moving heavy loads, efficiency and safety are paramount. Enter the VacuMaster Horizontal Vacuum Lifter—a game-changer in the world of material handling. This innovative device not only simplifies the process of transporting bulky items but also ensures that operators can work comfortably while maximising productivity. Imagine reducing strain on your workforce while enhancing workflow all at once. The VacuMaster is here to revolutionize how you approach heavy lifting tasks, offering a seamless solution for industries ranging from manufacturing to construction. Let’s dive deeper into what makes this vacuum lifter an essential tool for any operation dealing with hefty materials!

Benefits of Using a Vacuum Lifter

When it comes to lifting heavy loads, efficiency is key. A vacuum lifter streamlines processes, reducing the time required for manual handling. This boost in productivity can significantly enhance operational workflows.

Safety is another major advantage. Vacuum lifters minimise the risk of injury by eliminating awkward lifting positions and heavy strain on workers’ bodies. With ergonomic design, they promote a healthier workplace environment.

Moreover, these devices are gentle on materials. The non-damaging handling ensures that delicate surfaces remain intact during transport. Businesses can save money and resources by avoiding damage to products.

Additionally, vacuum lifters are versatile tools suitable for various applications across industries—from construction to manufacturing. Their adaptability allows companies to tackle diverse tasks efficiently while maintaining high standards of safety and reliability.

How Does the VacuMaster Work?

The VacuMaster Horizontal Vacuum Lifter operates on a simple yet effective principle. It uses vacuum technology to create a secure grip on various materials, allowing for easy lifting and transport.

When activated, the lifter generates a vacuum that adheres specifically to the surface of the load. This means it can handle items without causing any damage or leaving marks behind.

Equipped with an energy-efficient controlled vacuum generator, it ensures low operating costs while maintaining high performance. The robust construction combines steel, aluminum, and high-strength plastic for durability.

Additionally, safety features like a vacuum reservoir and audible warning device provide extra reassurance during operation. These components work together seamlessly to enhance efficiency while ensuring maximised safety for operators handling heavy loads effortlessly.

Ideal Applications for the VacuMaster

The VacuMaster Horizontal Vacuum Lifter shines in various industries. Whether you’re handling glass, metal sheets, or wooden panels, its versatility is unmatched.

In construction sites, it expertly lifts heavy materials with ease and precision. This reduces strain on workers while ensuring project timelines stay intact.

Manufacturing operations also benefit greatly from the VacuMaster’s efficiency. It streamlines processes by enabling quick loading and unloading of products without any damage.

Logistics companies find the device invaluable in warehouses for moving bulky items smoothly across storage areas. The non-damaging handling protects product integrity during transport.Fturbo

Additionally, furniture assembly lines utilise this lifter to maneuver large components effortlessly. Its ergonomic design safeguards operator health while increasing productivity levels dramatically.

Across all these applications, the VacuMaster enhances workflow consistency and safety simultaneously—a win-win situation for any business aiming to optimise their operations!

Advantages over Other Lifting Methods

The VacuMaster Horizontal Vacuum Lifter offers distinct advantages when compared to traditional lifting methods. Its vacuum technology enables smooth and precise handling of heavy loads without damaging the surfaces. This is especially beneficial for sensitive materials that require special care.

Unlike cranes or forklifts, the VacuMaster provides a more compact solution for tight spaces. Operators can maneuver effortlessly, reducing the risk of accidents in crowded work environments.

Moreover, this device promotes ergonomic lifting practices. It minimises strain on workers’ bodies, which helps maintain health and productivity over time.

Another key benefit lies in its low operating costs. The energy-efficient design ensures that users aren’t burdened with hefty utility bills while still enjoying top-notch performance.

With robust construction using steel, aluminum, and high-strength plastic, it promises durability and longevity unmatched by many conventional alternatives.

Maintenance and Safety Tips

Regular maintenance of the VacuMaster Horizontal Vacuum Lifter is essential for optimal performance. Check all components frequently, including hoses and seals, to ensure they are free from wear and tear.

Always inspect the vacuum generator for any leaks or malfunctions. A controlled vacuum generator not only aids efficiency but also contributes to low operating costs.

Safety should never be compromised. Make sure that operators are trained in proper handling techniques. This protects both the equipment and personnel during usage.

utilise the audible warning device effectively; it alerts users to potential issues before they escalate into serious problems.

Maintain a clean working environment around your lifting equipment. Debris can compromise functionality, increasing risks on-site.

A reliable solution…

The VacuMaster Horizontal Vacuum Lifter stands out as a reliable solution for efficient material handling. Its design prioritises increased productivity and maximised safety, which is essential in today’s fast-paced work environments. By utilising this innovative equipment, businesses can ensure the ergonomic well-being of their operators while minimising the risk of workplace injuries.

With its capability for non-damaging handling of heavy loads, the VacuMaster proves to be an invaluable asset across various industries. It combines low operating costs with robust construction materials like steel, aluminium, and high-strength plastic to deliver a long service life that you can depend on.

Whether you’re looking to streamline your operations or enhance safety protocols in your workplace, investing in a VacuMaster Horizontal Vacuum Lifter from Turbo Vacuumentation Ltd. could be one of the smartest decisions you make for your business’s future success.

Application

For handling large, flat and typically non-porous workpieces, for example:

- Loading and unloading CNC laser cutting machines with metal plates

- Loading and unloading CNC machining centres with wooden boards or plastic sheets

Handling and positioning glass panels and windows during production, framing and installation

- Your Benefits

- For handling large, flat and typically non-porous workpieces, for example:

- Efficient, non-damaging handling of heavy loads

- To work ergonomically and protect operator health

- Excellent work safety and process reliability thanks to vacuum reservoir and audible warning device

- Long service life due to a robust mixture of steel, aluminium and high-strength plastic

- Low operating costs thanks to controlled vacuum generator with energy saving (Comfort version)

- Design and Function

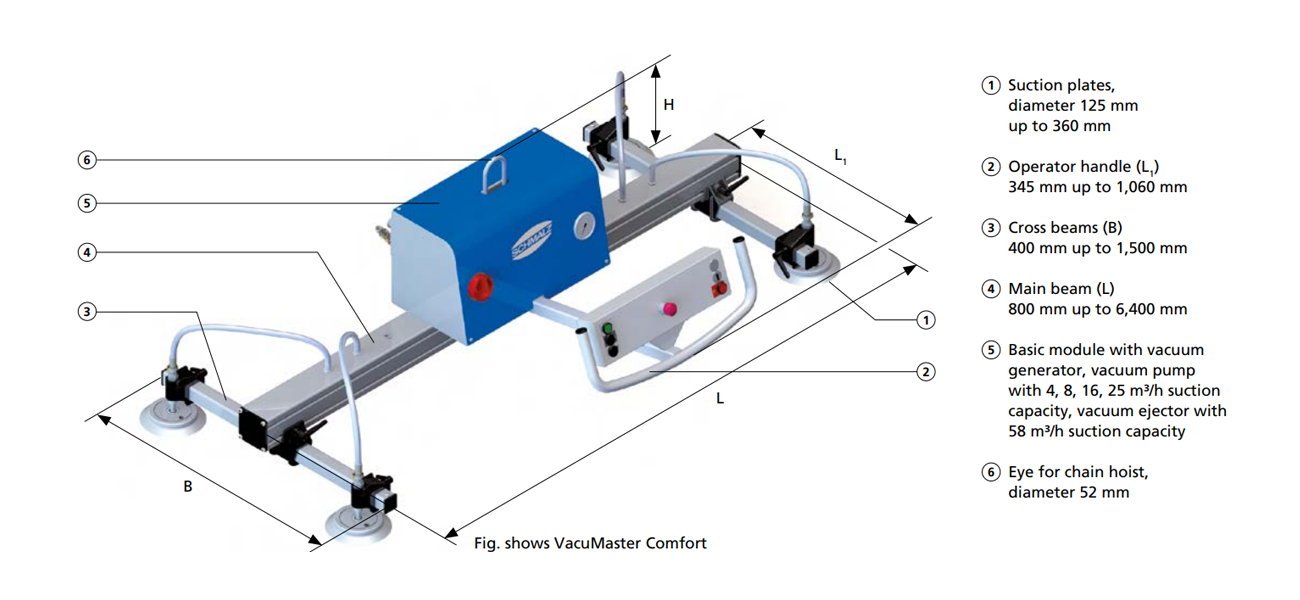

- The vacuum lifting device VacuMaster has a modular design. Various basic modules, operator handles, load beams and suction plates allow you to customize the configuration. The necessary suction force is generated by the vacuum generator and transferred to the workpiece via the suction plates. For safety purposes, the aluminium load beam also serves as a vacuum reservoir. A chain hoist is required for lifting or lowering motion, which Schmalz offers along with a compatible crane system.

- Our VacuMaster Range come with two control modules The VacuMaster Basic’s versatile standard equipment makes it indispensable for many applications. In addition, the VacuMaster Comfort offers an operator handle that brings together all of the device’s controls as well as a controlled vacuum generator for reducing energy.