Introduction to Jumbo Sprint Tube Lifters

In the fast-paced world of manufacturing and logistics, efficiency is king. Enter Jumbo Sprint Tube Lifters – your secret weapon for maximising productivity. These innovative lifting devices are designed to transform the way you handle heavy tubes and materials, streamlining operations like never before. Imagine effortlessly maneuvering hefty loads with precision and ease, all while reducing strain on your workforce. With numerous benefits that extend beyond just lifting, Jumbo Sprint Tube Lifters are revolutionising industries across the board. Let’s explore how these powerful tools can elevate your business practices to new heights!

Advantages and Uses of Jumbo Sprint Tube Lifters

Jumbo Sprint Tube Lifters offer a range of advantages that make them invaluable in various industries. Their ergonomic design significantly reduces the strain on workers, enhancing comfort during repetitive lifting tasks. This results in less fatigue and boosts employee morale.

These lifters are highly versatile, suitable for handling a wide variety of materials and tube types. Whether you’re moving heavy tubes or delicate components, Jumbo Sprint Tube Lifters adapt well to different weights and sizes.

Utilising these tools can maximise productivity on the shop floor. By streamlining material handling processes, companies experience more efficiency in their operations.

Furthermore, they enhance workplace safety by minimising accidents related to manual lifting. With fewer injuries reported, businesses can maintain smoother workflows without interruption caused by workforce downtime.

Features and Specifications

Jumbo Sprint Tube Lifters stand out in the realm of lifting equipment due to their innovative design and advanced technology. These lifters are engineered for handling a variety of tube sizes efficiently. They have a generous lift capacity up to 300 k.

Each model features powerful vacuum systems that ensure secure gripping, which maximises productivity during operations. With adjustable lifting heights, they can accommodate different work environments with ease.

Durability is key; constructed from high-quality materials, these lifters withstand heavy use while maintaining their performance. The ergonomic handles enhance user comfort, reducing fatigue over extended periods.

Additionally, safety mechanisms prevent accidental drops or slips, making them reliable for various industrial applications. Their lightweight nature allows for quick maneuvering without compromising strength or stability.

With an array of options tailored to specific needs, selecting the right Jumbo Sprint Tube Lifter becomes straightforward and beneficial for maximising efficiency on the job site.

How to Choose the Right Jumbo Sprint Tube Lifter for Your Needs

Selecting the right Jumbo Sprint Tube Lifter can significantly impact your workflow. Start by assessing the weight and dimensions of the materials you’ll be lifting. This ensures you choose a model that meets your load requirements without compromising safety.

Consider the environment where you’ll use the lifter. Different models are designed for various settings, such as warehouses or manufacturing floors. Ensure it aligns with your specific operational needs.

Evaluate any additional features that might enhance functionality, like adjustable height or ergonomic controls. These elements can maximise productivity and improve user experience.

Don’t forget to examine compatibility with other equipment in your facility. A well-integrated system leads to more efficiency in daily operations, streamlining processes across departments.

Consult customer reviews and product specifications thoroughly before making a decision; real-world experiences often reveal insights that numbers alone cannot convey.

Maintenance and Safety Tips

Regular maintenance is crucial for ensuring the longevity and performance of Jumbo Sprint Tube Lifters. Start by inspecting all components frequently. Look for wear and tear, loose connections, or any signs of damage.

Keep moving parts clean and well-lubricated. This reduces friction, enhances functionality, and boosts efficiency during operations.

Always follow manufacturer guidelines when performing any servicing tasks. Adhering to these instructions promotes safety and optimal performance.

Training your team on proper lifting techniques cannot be overlooked. Awareness about load limits helps prevent accidents in the workplace.

Conducting routine safety checks should become a habit. Ensure that emergency stop buttons are fully operational and accessible at all times to maximise productivity while reducing risks associated with heavy lifting equipment.

Comparison with Other Lifting Equipment

When comparing Jumbo Sprint Tube Lifters to other lifting equipment, several factors come into play. Traditional forklifts and hoists can be cumbersome in tight spaces where precision is key.

Jumbo Sprint Tube Lifters excel at maneuverability. Their lightweight design allows operators to handle items quickly without sacrificing safety or stability.

Unlike pneumatic lifters, which may require extensive maintenance, Jumbo models offer straightforward operation with minimal upkeep. This leads to increased uptime and maximises productivity across various applications.

Another advantage lies in their ergonomic design. While conventional lifting methods often lead to strain on workers, these tube lifters promote a healthier work environment by reducing physical stress.

In terms of efficiency, the streamlined process of using Jumbo Sprint Tube Lifters cuts down on time spent setting up and executing lifts compared to bulkier alternatives. Each lift becomes a smooth operation that enhances workflow significantly.

Buy Jumbo Sprint Tube Lifters From Turbo Vacuumentation Ltd

If you’re looking to enhance your operations, consider investing in Jumbo Sprint Tube Lifters from Turbo Vacuumentation Ltd. These innovative tools offer an array of advantages that can boost productivity and improve efficiency across various industries.

When you purchase from Turbo Vacuumentation Ltd, you gain access to high-quality equipment designed for durability and reliability. Their customer service team is knowledgeable and ready to assist with any queries regarding the best options for your specific needs.

Additionally, they provide comprehensive support, ensuring that you maximise the numerous benefits these lifters offer. Whether you’re handling heavy or awkward materials, their Jumbo Sprint Tube Lifters will simplify the process while prioritising safety.

Explore your options today and elevate your lifting capabilities with precision-engineered solutions tailored just for you!

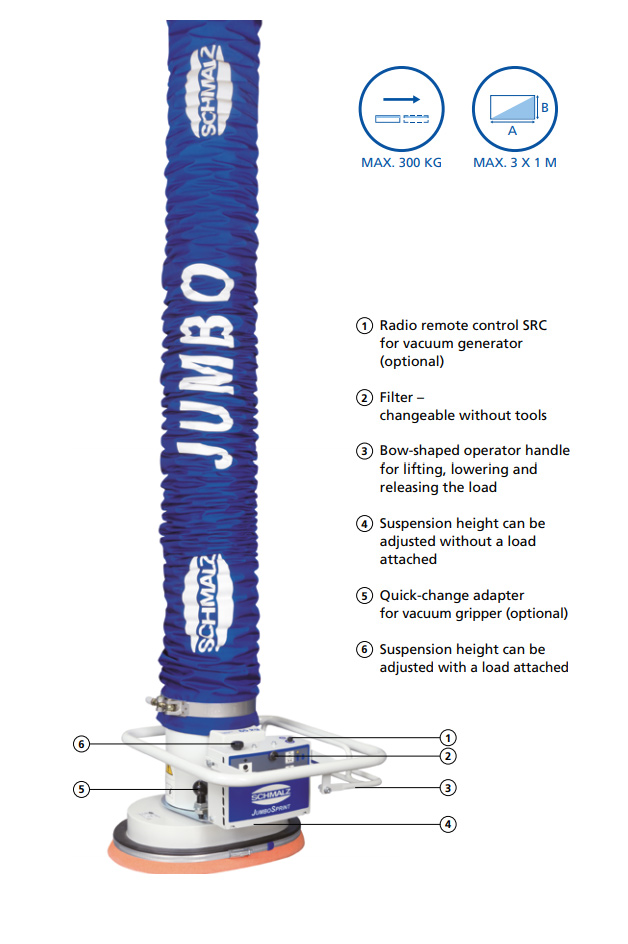

Jumbo Sprint

For compact workpieces

The Jumbo Sprint is equipped with a bow-shaped operator handle which extends all the way around the unit. This allows the user to optimally position it on compact goods such as bags or rubber bails. The load is raised by pulling up on the handle lever and lowered by pushing down.

Some more benefits of the Jumbo Ergo and Sprint Tube Lifters

Save up to 40% in energy with the push of a button

With the radio remote control SRC, you can directly switch off the vacuum generator on the operator handle when not in use and then back on again. The radio remote control is activated by a simple button push and needs no energy source due to an integrated solar cell.

Swivel workpieces by 90°

With the push of a button, the pneumatic swivelling unit PSE allows the user to swivel workpieces weighing up to 120 kg securely and in an ergonomic fashion.

Continuously rotate workpieces

With the rotation unit DE, gripped workpieces weighing up to 200 kg can be continuously rotated and positioned precisely.

maximise stack heights

High stacking heights are no problem with the movable operator handle (only for Jumbo Ergo). An optional locking mechanism allows it to be fixed at different angles.

Instantly release workpieces

The venting unit BEL allows non-porous workpieces to be released from the vacuum gripper and set down.

Reduce Sound Level

The silencer box SBB reduces the sound level of the vacuum generator and protects it from outside dirt. It can be easily mounted on the optional blower mounting platform.

Protection Against Dirt

The dust filter STF keeps dirt particles away from the vacuum generator and is always recommended to protect the generator. An optional differential pressure monitor with a signal lamp indicates when the dirty filter has to be changed.

Reach into deep containers

The hose-cylinder extension SZV enables ergonomic loading and unloading of containers such as lattice boxes.

Protection against thermal overload

With the motor-protection switch MSS the vacuum generator can be switched on/off and protected against overcurrent. It can be integrated into the Schmalz crane column without the need for complicated wiring and can be optionally locked.