Imagine a world where industrial processes are streamlined, productivity soars, and workers can focus on what truly matters. Enter vacuum gripping systems – a game-changer in automation and material handling. These innovative solutions harness the power of suction to lift, move, and manipulate objects with precision and ease. Whether you’re in manufacturing, logistics, or any sector that relies on efficiency, understanding these systems may very well be your next step toward operational excellence. Let’s drill down into why vacuum gripping systems deserve your attention!

Advantages of Using Vacuum Gripping Systems

Vacuum gripping systems offer a multitude of benefits that can enhance operational efficiency. Their ability to securely hold various materials makes them invaluable in manufacturing and logistics.

One of the key advantages is versatility. These systems can handle different shapes and sizes, adapting swiftly to diverse tasks without extensive reconfiguration.

Safety is another significant factor. Unlike traditional mechanical grips, vacuum grippers reduce the risk of damage to delicate items, ensuring they remain intact during transport.

Moreover, they provide consistent performance under varying conditions. Whether dealing with smooth or textured surfaces, vacuum gripping technology maintains its grip reliability.

Efficiency also plays a pivotal role; reduced cycle times lead to increased productivity on production lines. The simplicity of installation further streamlines integration into existing workflows, making it an attractive option for many businesses looking to optimise their operations.

Types of Vacuum Gripping Systems

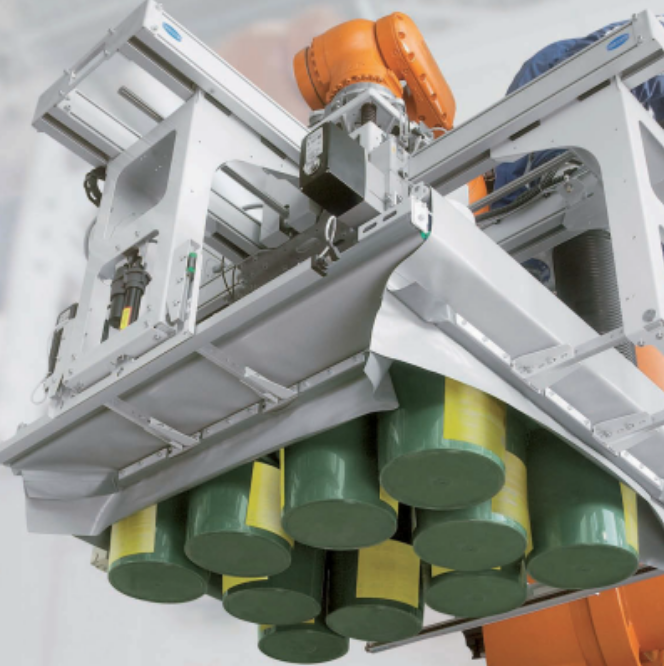

Vacuum gripping systems come in various designs, each tailored to specific tasks and materials. One popular type is the Layer Gripper. These grippers are designed to handle multiple layers of products simultaneously, making them ideal for industries dealing with stacked items.

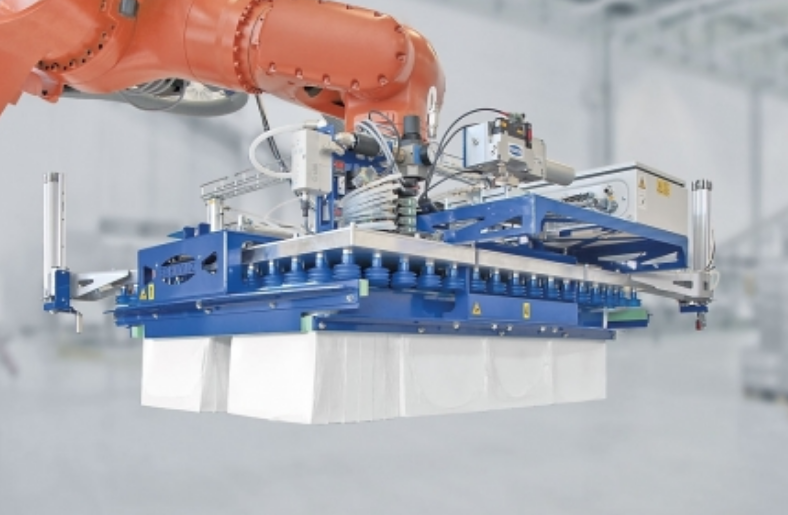

Suction Spiders are another innovative option. With their unique configuration of suction cups arranged in a spider-like pattern, they can securely grasp irregularly shaped objects. This versatility makes them invaluable in manufacturing settings where precision is crucial.

Special Gripping Systems cater to unique requirements such as handling delicate or fragile components. These systems often incorporate softer materials or custom configurations to prevent damage during transport.

Gripper systems for end-of-arm robot tooling showcase advanced engineering that allows robots to pick up and manipulate parts seamlessly. Each system plays a pivotal role in enhancing efficiency across diverse applications while ensuring safety and reliability.

Applications of Vacuum Gripping Systems

Vacuum gripping systems have a wide range of applications across various industries. In manufacturing, they efficiently handle delicate components like glass sheets or electronic circuit boards without causing damage. Their ability to maintain grip on fragile items makes them invaluable in assembly lines.

In the food industry, these gripping systems are utilised for packaging and sorting tasks. They can carefully lift and place products such as fruits, vegetables, and packaged goods with minimal risk of contamination.

Logistics companies also benefit from vacuum grippers when moving heavy packages. These systems facilitate quick loading and unloading processes while ensuring safety during transit.

Additionally, in the automotive sector, special gripping systems assist in assembling parts by securely holding multiple components at once. This versatility highlights how crucial vacuum gripping technology has become to modern operations across diverse sectors.

Cost-Effectiveness and Efficiency of Vacuum Gripping Systems

Vacuum gripping systems are not just innovative; they also deliver impressive cost-effectiveness. By minimising downtime and increasing production speed, businesses can see a rapid return on investment.

These systems streamline operations by reducing the need for manual handling. This leads to fewer labor costs and less risk of workplace injuries.

Maintenance requirements are generally low as well, making them an attractive option for companies looking to cut expenses without sacrificing quality.

On top of that, vacuum grippers adapt easily to various materials and shapes. Their versatility allows manufacturers to optimise processes across multiple applications, maximising efficiency further. TVL can help ensure that you choose the right product for you!

When you consider energy consumption, many modern vacuum gripping systems have been designed with energy-efficient technologies in mind. This means lower utility bills over time while maintaining high performance levels.

How to Choose the Right Vacuum Gripping System for Your Business

Choosing the right vacuum gripping system for your business involves several key considerations. First, assess the materials you will handle. Different surfaces require specific gripper systems to ensure optimal adhesion.

Next, think about the weight and size of items being moved. Layer Grippers or Suction Spiders may suit lighter loads, while heavier items might need robust Special Gripping Systems that can provide extra support.

Evaluate your production environment as well. Will these systems be exposed to dust or moisture? Certain designs offer enhanced durability in such conditions.

Don’t overlook compatibility with existing robotic arms. The best gripper systems for end-of-arm robot tooling should seamlessly integrate into your workflow without causing disruptions.

Consider future scalability. Opting for a flexible solution now can save costs later as your operations grow and evolve. Look ahead; it makes all the difference in long-term efficiency.

A Vital Component

Vacuum gripping systems have become a vital component in modern automation and manufacturing processes. The advantages they offer—such as increased efficiency and versatility – cannot be overstated. With various types available, including Layer Grippers, Suction Spiders, and Special Gripping Systems, businesses can find the perfect solution to meet their unique needs.

These systems are not just limited to one industry; their applications span across sectors like packaging, automotive assembly, and electronics. This adaptability makes them indispensable for companies looking to streamline operations.

When considering cost-effectiveness, vacuum gripping systems often provide a significant return on investment through enhanced productivity and reduced labor costs. Choosing the right gripper system for end-of-arm robot tooling is crucial for maximising these benefits while ensuring compatibility with existing workflows.

The growing demand for innovative solutions in handling tasks positions vacuum gripping systems at the forefront of industrial automation trends. As technology advances further, embracing these tools will likely lead to even greater efficiencies and opportunities within your business landscape.