In the ever-evolving world of manufacturing and woodworking, efficiency is key. Enter vacuum clamping technology – a game-changer that redefines how we secure materials during processing. Imagine a system that holds your workpieces in place without the fuss of traditional clamps or vises. With advancements in this innovative technology, manufacturers are discovering new ways to enhance productivity while maintaining precision and quality.

Vacuum clamping eliminates many of the hassles associated with conventional methods, paving the way for streamlined operations and improved performance across various applications. If you’re curious about what makes vacuum clamping a go-to solution for modern machining centers, you’re in the right place! Let’s explore its types, benefits, processes, and much more to see if it truly is the answer you’ve been searching for.

Different types of vacuum clamping systems

Vacuum clamping systems come in various forms, each tailored for specific applications.

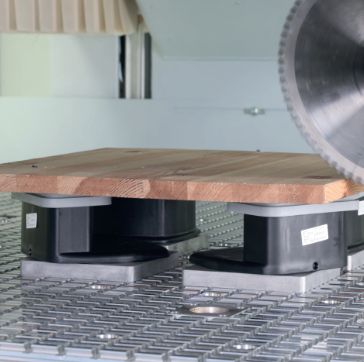

Grid Table Systems vacuum blocks for grid tables enable simple and flexible use without complex installation. The non-slip fixings enable secure clamping of the workpieces even with high machining forces. This makes them ideal for complex five-axis applications without a wear plate.

Console Table Systems are designed for efficiency and flexibility. They provide stable support while accommodating different workpieces with ease.

Flat Table Systems excel on level surfaces, enabling quick setups. This design simplifies the process, making it ideal for projects requiring rapid changes.

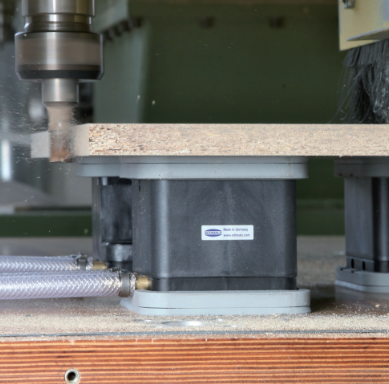

Clamping Innospann focuses on modernizing CNC machining centers. It enhances precision and user experience by integrating advanced features into existing setups.

Then there’s the Clamping Multi Clamp, which significantly aids in manually fixing and machining workpieces. Its versatility makes it a popular choice among operators seeking reliability without sacrificing performance.

Each type of vacuum clamping system brings unique advantages to the table, catering to diverse needs across industries.

Benefits of Vacuum Clamping Technology

Vacuum clamping technology offers a multitude of benefits that can transform the way you work.

First and foremost, it enhances efficiency by securely holding materials in place without the need for bulky clamps or fixtures. This allows for faster setup times and smoother operations.

The versatility of vacuum systems is another significant advantage. They accommodate various shapes and sizes, making them ideal for different projects. Whether you’re dealing with delicate components or heavy-duty pieces, vacuum clamping adapts seamlessly.

In terms of safety, this technology reduces the risk of accidents caused by traditional clamping methods. With a solid grip on workpieces, operators can focus on their tasks without worries about sudden shifts.

Additionally, vacuum clamping minimizes surface damage. It avoids marks often left behind by mechanical clamps, ensuring high-quality finishes every time you complete a project.

How it works: Understanding the Process

Vacuum clamping technology operates on a simple yet effective principle. It uses atmospheric pressure to secure workpieces firmly in place.

The process begins with the placement of a workpiece onto a specially designed vacuum table. This surface features multiple channels that connect to a vacuum pump.

When the pump is activated, air is removed from the space between the workpiece and the table. As air escapes, atmospheric pressure pushes down on the item, creating an incredibly strong hold.

This method provides an even distribution of clamping force across all contact points, ensuring stability during machining operations.

Any adjustments can be made quickly without lengthy setups or additional tools required for traditional fixtures.

This flexibility allows operators to switch tasks seamlessly while maintaining precision and quality throughout production processes.

Applications of Vacuum Clamping Technology

Vacuum clamping technology finds its place in various industries, showcasing remarkable versatility. It is especially prevalent in woodworking, where it secures large panels for precision cutting and finishing. The ability to hold materials firmly without mechanical fasteners simplifies complex operations.

In the automotive sector, vacuum systems are used to position intricate parts during assembly. This method enhances accuracy while reducing the risk of damage to sensitive components.

The aerospace industry also benefits from vacuum clamping for machining lightweight materials like composites and aluminum alloys. Here, maintaining tight tolerances is crucial for safety and performance.

Moreover, packaging companies utilize this technology for efficient product placement on production lines. Quick setups allow them to switch between different products seamlessly.

From CNC machining centers modernizing their processes to manual workpiece handling with multi clamps, vacuum clamping proves indispensable across multiple applications. Its adaptability enables improved workflow in diverse environments.

Comparison with Traditional Clamping Methods

Traditional clamping methods often rely on mechanical fixtures and vises, which can be cumbersome. These systems require precise alignment and significant manual effort to secure workpieces. This process can slow down production time.

In contrast, vacuum clamping technology simplifies the setup. A strong vacuum holds the workpiece securely without the need for physical clamps that might obstruct machining access.

Moreover, traditional methods may introduce marks or imperfections on surfaces due to pressure points from clamps. Vacuum systems eliminate this risk by providing even pressure across the entire surface.

Flexibility is another key difference. While classic clamps are limited by their design, modern vacuum solutions adapt easily to various shapes and sizes of materials—ideal for custom projects in CNC machining settings.

The safety aspect cannot be ignored either; traditional setups sometimes lead to accidents if they fail during operation, whereas vacuum systems enhance stability and reduce risks significantly.

Cost and Maintenance Considerations

When evaluating vacuum clamping technology, cost is a significant factor. Initial investment can seem steep compared to traditional methods. However, consider the long-term savings from improved efficiency and reduced labor costs.

Maintenance is another aspect that deserves attention. Vacuum systems generally require less upkeep than mechanical clamps. Regular checks on seals and filters ensure optimal performance.

Potential repairs are minimal but should be anticipated in budgeting plans. Investing in quality components reduces frequent replacements and associated downtime.

Training staff on proper usage also plays a role in overall costs. While it might involve some initial expenditure, well-trained operators minimize errors and maintain high productivity levels.

Balancing upfront costs against operational benefits paints a clearer picture of value within any production environment utilizing vacuum clamping technology.

Is Vacuum Clamping Technology the Answer?

Vacuum clamping technology presents a compelling solution for various manufacturing challenges. Its ability to securely hold workpieces without the need for mechanical clamps makes it ideal for modern production environments. With options like Console Table Systems, which offer efficiency through flexibility and quality, and Flat Table Systems that enable quick setups on flat surfaces, manufacturers can streamline their processes significantly.

The advantages of vacuum clamping are numerous—improved efficiency leads to greater performance while also enhancing safety in the workplace. Additionally, systems such as Clamping Innospann modernize CNC machining centers by integrating advanced features that facilitate intricate tasks with ease. The versatility offered by solutions like Clamping Multi Clamp greatly assists in the manual fixing and machining of workpieces across different applications.

While cost and maintenance considerations play a role in decision-making, many find that the benefits outweigh these factors over time. As industries continue to evolve towards automation and precision engineering, vacuum clamping technology stands out as an innovative answer to meet demands for speed and accuracy in manufacturing processes. Whether you are looking to enhance existing operations or adopt new technologies, exploring vacuum clamping could be a wise investment moving forward.