When it comes to designing efficient and reliable systems, the right vacuum components can make all the difference. Whether you’re in manufacturing, robotics, or packaging, these essential elements are fundamental for achieving optimal performance. With a variety of options available—from Vacuum Suction Cups to advanced Valve Technology—understanding how each component contributes to your application is crucial. Let’s dive into the world of vacuum components and discover how you can build your individual vacuum system tailored to your specific needs.

Understanding the Different Types of Vacuum Components

Vacuum components play a crucial role in various applications, each designed for specific tasks. Among the most common are vacuum suction cups. These versatile tools cling to surfaces, ensuring secure handling of items during production processes.

Special grippers offer another layer of functionality. They adapt to different shapes and sizes, providing flexibility when manipulating products. This adaptability enhances efficiency in manufacturing environments where precision is key.

When it comes to larger objects or complex geometries, vacuum area grippers shine. Their broad surface contact allows for stable lifting without damaging delicate materials.

Mounting elements are essential as well; they provide the backbone for assembling your vacuum system correctly. The right mounting strategy ensures that all components work harmoniously together.

Don’t overlook vacuum generators—they create the necessary suction power required by these systems. Meanwhile, valve technology regulates airflow effectively, keeping operations smooth and controlled throughout every task in a myriad of industries.

Importance of Choosing the Right Vacuum Components for Your Application

Selecting the right vacuum components is crucial for efficiency and performance. Each application has specific requirements, from the materials involved to environmental conditions.

Using inappropriate components may lead to inefficiencies or even system failures. For instance, if you choose a vacuum generator that lacks sufficient power for your needs, it can impede productivity.

Moreover, different tasks require unique features. Vacuum suction cups vary in shape and material depending on what they are lifting. Understanding these distinctions helps achieve optimal results.

Compatibility among parts also plays a significant role. When every component works seamlessly together, your entire system operates more smoothly.

This thoughtful selection process ensures reliability over time while minimizing maintenance costs and downtime. The investment in quality vacuum components pays off through enhanced operational capabilities tailored specifically to your application’s demands.

Factors to Consider When Selecting Vacuum Components

Selecting vacuum components requires careful consideration of several factors. First, the application’s specific requirements should dictate your choices. Different processes demand different levels of suction and control.

Next, assess the material compatibility. Certain substances may react negatively with particular materials used in vacuum components, affecting performance and longevity.

Size is another crucial aspect. The physical dimensions must fit within your existing setup while providing adequate functionality.

Also, consider energy efficiency. Choosing components that minimize power consumption can enhance overall system performance and reduce operational costs over time.

Don’t overlook maintenance needs either; easy-to-maintain components save time and resources in the long run. Ensure you have access to reliable support from manufacturers for installation or troubleshooting assistance when needed. Each factor plays a vital role in building an effective vacuum system tailored to your unique needs.

Creating the Perfect Solution with Vacuum Components

Creating the perfect solution with vacuum components requires a thoughtful approach. Your application’s specific needs dictate which components will work best. From Vacuum Suction Cups to Special Grippers and Vacuum Area Grippers, each piece plays a vital role.

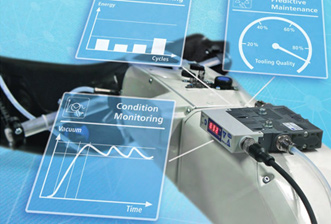

Selecting suitable Mounting Elements is crucial for stability and performance. Don’t overlook the importance of reliable Vacuum Generators and advanced Valve Technology that can enhance efficiency in your system. Integrating appropriate Switches & System Monitoring ensures seamless operation, while Filters and Connections maintain cleanliness throughout your setup.

Cutting-edge vacuum components provide users across diverse industrial sectors with dependable assistance in addressing automation and handling challenges. The extensive selection of these components encompasses suction pads, vacuum generators, mounting elements, and system monitoring tools. TVL offer a comprehensive inventory of vacuum components, supplying everything necessary to create your customised vacuum system, including Vacuum Suction Cups, Special Grippers, Vacuum Area Grippers, Mounting Elements, Vacuum Generators, Valve Technology, Switches & System Monitoring and Filters and Connections.

By carefully considering these factors, you can build your individual vacuum system with our vacuum components to achieve optimal results. With the right combination of elements, you’ll maximize productivity and reliability in all applications involving vacuum technology. The journey towards achieving an ideal solution starts with understanding what works best for you!