Manual handling is an essential part of many workplaces, especially those that involve heavy lifting. Whether you’re in a warehouse, factory, or construction site, knowing how to handle loads safely can make all the difference. From preventing injuries to improving efficiency, proper manual handling techniques are crucial for maintaining a productive work environment.

Heavy lifting often comes with risks—strains and sprains are common if safety measures aren’t followed. But fear not! With the right knowledge and tools at your disposal, you can tackle even the heaviest tasks without breaking a sweat. Let’s delve into the world of manual handling options designed specifically for heavy lifting and discover how they can transform your workplace dynamics.

The Importance of Proper Manual Handling Techniques

Proper manual handling techniques are vital for ensuring safety in any workplace. When employees lift, carry, or move heavy objects incorrectly, it can lead to serious injuries. Back strains and musculoskeletal disorders are common consequences of poor lifting practices.

Using correct techniques helps reduce the risk of injury significantly. It promotes body mechanics that align with natural movements, allowing individuals to handle loads more efficiently and safely.

Additionally, proper training in manual handling fosters a culture of safety within an organisation. Employees who understand how to manage their loads better will feel more confident in their tasks. This confidence translates into higher productivity levels as workers focus on their responsibilities without fear of injury.

Investing time and resources into educating staff about effective manual handling can save businesses from costly medical bills and lost workdays due to accidents. Emphasising these techniques is essential for maintaining a healthy workforce.

Different Types of Manual Handling Equipment

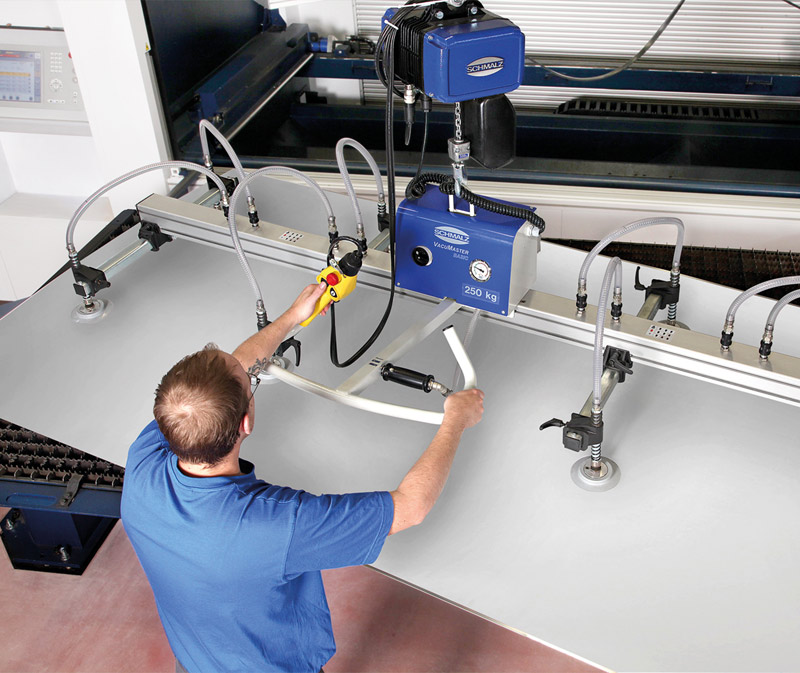

Manual handling equipment comes in various forms, each designed to make lifting and moving easier. One popular option is the VacuMaster, which utilises vacuum technology to lift heavy loads securely. This system allows for quick maneuvering while reducing strain on workers.

Jumbo Tube Lifters are another innovative choice. These devices use lightweight yet strong tubing to lift and lower items with precision. They’re perfect for repetitive tasks, significantly increasing efficiency.

For more traditional needs, trolleys and pallet jacks remain staples in many workplaces. These tools help transport goods without requiring direct lifting from employees.

Additionally, ergonomic aids like lifting straps or hoists provide extra support during heavier lifts. Investing in appropriate workshop equipment can enhance safety standards while allowing loads to be handled faster and more securely within any environment.

Tips for Implementing Safe Manual Handling in the Workplace

Creating a safe manual handling environment starts with training. Ensure that all employees understand proper lifting techniques. This knowledge reduces the risk of injury significantly.

Encourage regular breaks to prevent fatigue. Tired workers are more prone to accidents, making it essential to allow time for recovery.

Use appropriate equipment like VacuMaster or Jumbo Tube Lifters whenever possible. These tools can make heavy lifting easier and safer, allowing loads to be handled faster and more securely.

Implement clear communication among team members during tasks involving heavy items. A coordinated effort reduces risks associated with miscommunication.

Regularly assess your workplace layout as well. Keeping pathways clear and arranging materials logically can enhance safety and efficiency in manual handling activities.

A Critical Aspect

Manual handling is a critical aspect of many industries, especially when it comes to heavy lifting. Proper techniques not only ensure the safety of employees but also enhance productivity. With the right equipment, such as VacuMaster and Jumbo Tube Lifters, workplaces can allow loads to be handled faster and more securely.

Implementing safe manual handling practices in your environment doesn’t have to be complicated. By investing in appropriate workshop equipment and training staff on best practices, businesses can significantly reduce risks associated with heavy lifting tasks. Remember that a workplace solution should consist of both a handling system and a crane designed to work perfectly together.

Focusing on these elements creates an efficient workflow while prioritising safety for all involved. As you consider how to improve your manual handling processes, think about where enhancements can make the most impact within your operations. Prioritising proper techniques and suitable tools ensures everyone goes home safely at the end of each day while boosting overall efficiency.

In various industries, vacuum handling systems are utilised to streamline material flows. With our extensive expertise and strong client partnerships, we possess a thorough understanding of your operations, enabling us to deliver top-quality products that meet exceptional criteria. By utilising our efficient and safe handling systems, both your materials and employees are protected while allowing for faster operations. We can offer you a comprehensive workplace solution, including a perfectly compatible crane, at your convenience.