When it comes to heavy lifting, traditional methods can be cumbersome and often put worker safety at risk. Enter VacuMaster Lifting Devices – the game-changer in the world of material handling. This innovative solution simplifies the task of moving heavy objects like metal plates, wooden boards, and glass sheets, allowing a single operator to handle loads that would typically require an entire team. With their advanced vacuum technology, these devices not only make lifting easier but also prioritise employee health by reducing physical strain. Curious about how they work and why they’re becoming essential tools across various industries? Let’s delve into everything you need to know about VacuMaster Lifting Devices!

How do VacuMaster Lifting Devices work?

VacuMaster Lifting Devices operate on a simple yet effective principle: the power of vacuum. These devices create a suction force that securely grips various materials, from metal to glass.

Once placed on the workpiece, the device forms an airtight seal. This allows it to lift heavy loads effortlessly. The operator can then maneuver and position items without straining their body.

The technology behind these lifting devices is advanced but user-friendly. Operators just need to activate the vacuum pump, which generates suction in seconds.

Safety features are built-in as well, ensuring that if there’s any loss of power or pressure, the load remains secure for a safe operation. Whether handling large sheets or barrels, VacuMaster simplifies heavy lifting tasks with remarkable efficiency and reliability.

Benefits of using VacuMaster Lifting Devices

VacuMaster Lifting Devices offer numerous advantages that make them an essential tool in various industries. First and foremost, they significantly reduce the physical strain on workers. By utilising vacuum technology, these devices enable a single operator to lift heavy materials easily.

Efficiency is another key benefit. The speed at which items can be moved increases productivity, streamlining operations and reducing downtime. This translates into cost savings for businesses.

Safety is paramount when handling heavy loads. VacuMaster minimises the risk of injuries related to lifting and carrying, promoting a safer workplace environment.

Moreover, these devices are versatile; they can handle different materials like metal plates, glass sheets, or wooden boards with ease. Their adaptability makes them valuable assets across multiple applications and industries.

The quality of work improves thanks to reduced chances of damage during transport or installation tasks.

Applications and Industries that can benefit from VacuMaster Lifting Devices

VacuMaster Lifting Devices find their place across a multitude of industries. From construction to manufacturing, these devices are engineered to enhance productivity and safety.

In the glass industry, they streamline the handling of heavy sheets with precision. Workers can effortlessly maneuver large panes where traditional lifting methods would struggle.

The automotive sector also benefits significantly. Whether moving heavy metal components or delicate parts, VacuMaster ensures that every task is handled smoothly and efficiently.

Woodworking shops leverage these devices for transporting lumber and panels. This not only speeds up production but reduces strain on workers’ bodies.

Additionally, in warehouse settings, VacuMasters simplify loading and unloading tasks. By minimising manual handling, companies can maintain high efficiency while prioritising employee health.

From factories to shipping docks, the versatility of VacuMaster Lifting Devices makes them indispensable tools in numerous fields.

Types of VacuMaster Lifting Devices and their features

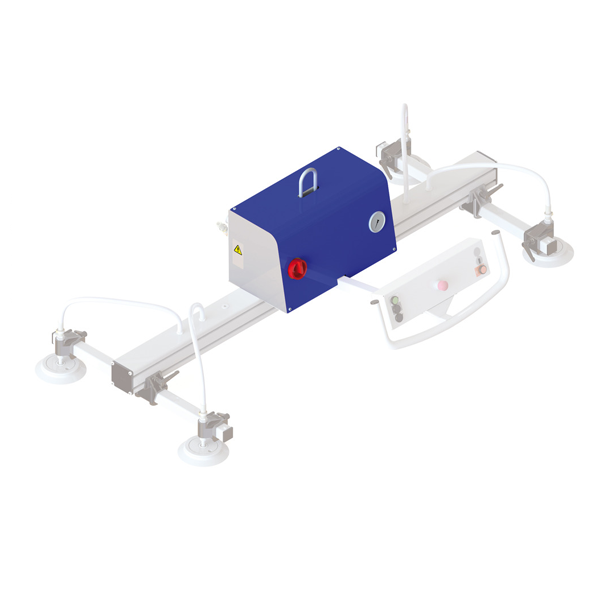

VacuMaster Lifting Devices come in various types, each tailored for specific tasks. The VacuMaster Basic is ideal for general lifting needs, featuring a simple design that provides reliable support for flat surfaces.

For projects requiring versatility, the VacuMaster Multi demonstrates adaptability with its adjustable suction pads. This model can handle different materials and shapes effortlessly.

In contrast, the VacuMaster Glass offers specialised features like soft rubber pads to protect delicate surfaces while ensuring a secure grip on glass sheets. It’s perfect for contractors working in construction or glazing.

Be sure to take a look at various other VacuMaster range, including the VacuMaster Horizontal, the VacuMaster 90° Rotate, the VacuMaster 180° Rotate, the VacuMaster Vaio, the VacuMaster Eco, the VacuMaster HHVM, the VacuMaster HVB, the VacuMaster Coil, the VacuMaster Light and the VacuMaster Window.

Each device incorporates user-friendly controls and safety mechanisms to enhance operational efficiency while reducing strain on workers. These diverse options make choosing the right model easy based on project requirements.

Safety precautions when using VacuMaster Lifting Devices

Safety is paramount when operating VacuMaster Lifting Devices. Proper training for all users is essential to ensure they understand how the equipment functions and its limitations.

Always inspect the lifting device before use. Check for any signs of wear or damage, especially on seals and hoses. This simple step can prevent accidents and extend the lifespan of your equipment.

Ensure that the load being lifted is within the device’s specified weight capacity. Overloading can lead to failures and hazardous situations.

Use appropriate personal protective equipment (PPE) such as gloves, safety goggles, and hard hats while operating these devices. Your health should never be compromised.

Maintain a clear workspace free from obstacles to allow safe maneuverability during operations. This helps in preventing injuries related to tripping or collisions while handling heavy loads with ease.

Never attempt repairs without proper authorisation or expertise; always consult a professional if issues arise with your VacuMaster Lifting Device.

What customers are saying about VacuMaster Lifting Devices

Customers across various industries are singing the praises of VacuMaster Lifting Devices. Many users highlight their efficiency in handling heavy materials like metal sheets and glass panels. The ease of operation has transformed workflows, enabling one person to do what once required multiple hands.

Feedback often notes the device’s reliability under pressure. Users appreciate that it minimises physical strain while maximising productivity. This balance is crucial for workplaces where safety is paramount.

Another point frequently mentioned is its versatility. From construction sites to manufacturing plants, operators express satisfaction with how well VacuMaster adapts to different tasks and environments.

Several reviews emphasise the user-friendly design, making training quick and seamless. It’s clear that customers feel empowered, able to tackle challenging jobs without worry or fatigue. Their confidence in using this technology speaks volumes about its impact on daily operations.

Why VacuMaster Lifting

The VacuMaster Lifting Devices stand out as a revolutionary solution for material handling challenges. Their innovative design allows operators to lift and maneuver heavy items with ease, enhancing productivity while prioritising safety. The range of applications across various industries speaks volumes about their versatility and effectiveness.

With minimal manpower required, these devices not only streamline operations but also reduce the risk of workplace injuries. Businesses that have integrated VacuMaster into their processes report marked improvements in both efficiency and employee satisfaction.

Choosing VacuMaster means investing in quality, reliability, and advanced technology. For any organisation looking to elevate its lifting capabilities, the benefits are clear: enhanced safety measures protect your workforce while maximising output potential.

For those seeking an edge in material handling tasks—from construction sites to manufacturing plants—the advantages offered by VacuMaster Lifting Devices make them a top choice worth considering.